Desire: Easy integration of stepper motor for linear motion application.

Idea: Use Pololu item 2690 and drive with Adafruit DRV8833.

Question: Is it safe and desirable to use this driver with this motor?

Design considerations: I don’t care about the speed, and prefer to have as much torque available as possible. I have not yet selected a power supply, but plan on using a buck converter to reduce the voltage. I know there are drivers available on Pololu which can support this motor, but seem to need programming in a way that I’m not familiar with, so I’d like to avoid learning/using/troubleshooting a brand new software if I can stick with Arduino.

Research: Used product pages of each, and Matching Stepper Motor and Driver.

My thoughts: Since I can use the driver with a supply voltage down to 2.7V, which is the stepper’s rating, and the driver is current limited to 1A per phase, then I will just not get quite as much torque as the max holding torque if the driver supplied the 1.7A that the motor could handle, right?

Thanks in advance for any and all advice and help!

Hello.

You can use that stepper motor and driver together, but like you said, you will not be able to get the full power possible out of your motor since that stepper driver has a lower rated current per phase than the motor. Depending on your size constraints, you might consider using our TB67S249FTG compact driver carrier, or our TB67S249FTG full breakout which will allow you to get much more power out of your motor.

We do not have an Arduino library for those drivers; however, it uses the same step/dir interface used by many stepper motor drivers. There are many Arduino libraries that support that type of interface, like this one, so you could probably use one with the TB67S249FTG (or modify one to work with it if that is even necessary).

By the way, it sounds like you might think that you need to regulate your supply voltage down to the rated voltage of your stepper motor, but as long as you are using a driver with automatic current limiting (which is how all of our stepper motor drivers operate) then you can use any voltage that is higher than your stepper’s rated voltage and within the limits of what the driver can handle. In fact, there are actually some benefits to using a higher supply voltage. You can find more about this under the FAQs tab for our stepper motors and our stepper motor drivers.

- Patrick

Thanks you, Patrick!

Follow up question: Although speed isn’t as important in my application, I’m curious exactly what Pololu used to drive your stepper motor Item 2690 up to 12 in/s. E.g. supply voltage, mode, acceleration, etc.

I ended up getting a Tic T249, and using 12 V supply, set to max current amps for item 2690 (1680mA), full step mode, I lose steps around 1 in/s linear motion when set on the benchtop like in your demo gif on the product page.

Unfortunately, we did that test several years ago, and I could not find the specific operating conditions we used, other than the fact we used a DRV8825. However, there are a few things you can try to increase your stepper motor’s maximum speed. I suggest you try decreasing the acceleration rate, increasing the microstepping ratio (along with a corresponding increase in the rate you’re sending step pulses) , and increasing your supply voltage if possible.

- Patrick

Hi Patrick,

It seems my results are very much motor dependent; I have one 38cm lead screw #2690 and one 28cm lead screw #2268.

The 28cm can accelerate quickly, and I am getting top speeds of over 22 in/s using your Tic T249, 29,000 pulses per second (pps), 1/2 step, 2,000 pulse per second^2 acceleration, and operating voltage to the Tic of ~11.7V.

The 38cm on the other hand, using the same settings, stalls at ~4000 pps, or ~Pi inches per second. Each doubling of the microstepping only doubles the pps at which stall occurs, but is the same linear distance/s (and same RPM, ~600).

It doesn’t seem like the rod inertia, ~m*r^2 should cause a ~ 1/7h reduction in speed. Is there perhaps something wrong with my 38cm motor (through either manufacturing or user error)?

It seems very unlikely that something is wrong with the motor, can you tell me more about how you are testing the motors, such as what your power supply is and if you have anything connected to the stepper motor? Could you post some pictures of your setup as well as your Tic settings file? You can save your settings file from the Tic Control Center under the “File” menu with the controller connected.

- Patrick

Thanks for your help, Patrick.

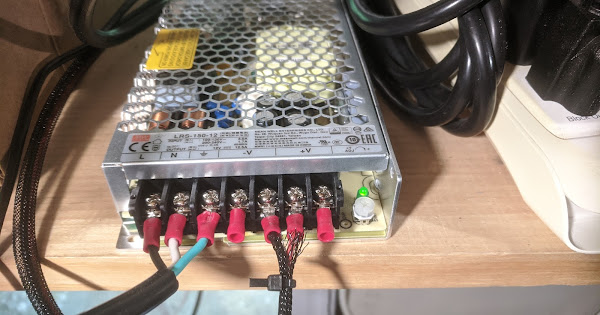

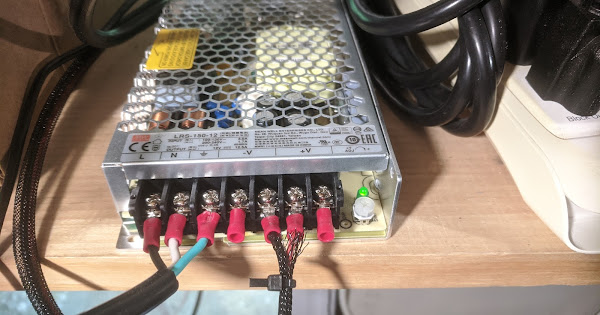

Power Supply: Mean Well LRS-150-12 (12 V 150W)

The only things on each stepper motor is a thrust bearing and lock collar, but they were not loaded (lock collar above each thrust bearing). I didn’t think that would make much of an effect, but because of your question, I tried removing them and it sure evened the playing field. Now they both stall at 6000 (38cm) and 10000 (28cm) pulses per second.

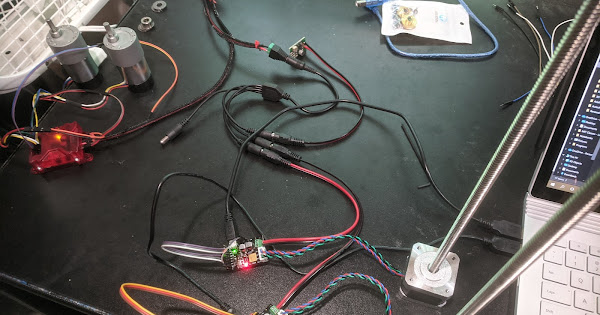

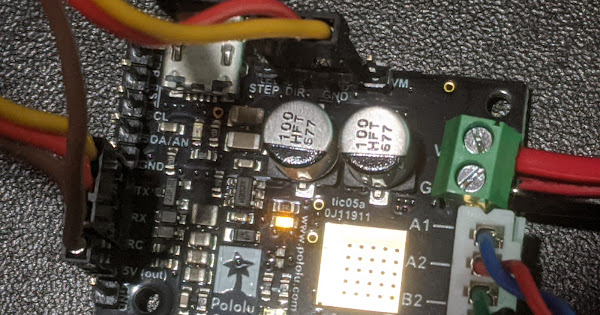

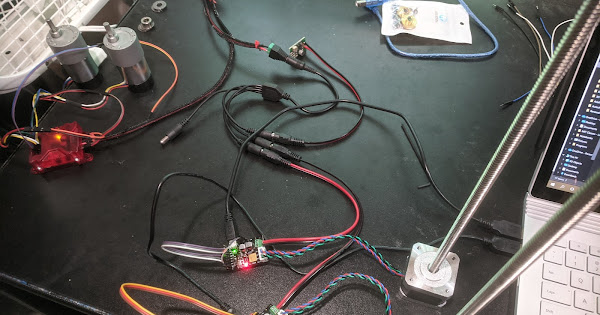

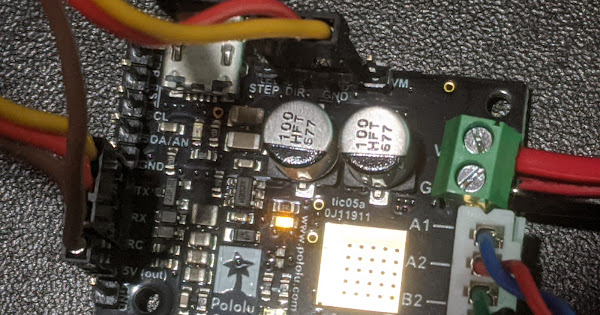

To explain the wiring, I have limit and kill switches set for each Tic, and instead of actual switches wired at the moment, I’m connecting to on board ground and 5v to enable each one.

Also powered in the photo is a shunt regulator and a roboclaw, but the roboclaw is not driving the other motors currently.

Settings and photos attached.

tic_settings 28CM.txt (1.4 KB) tic_settings 38CM.txt (1.4 KB)

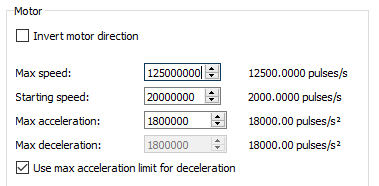

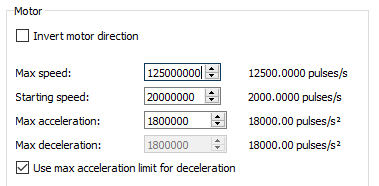

Thank you for the pictures, setting files, and extra information. I noticed from your settings file that you are running in half-step mode and your maximum speed setting of 30000pps. That corresponds to twice the 30cm/s speed we mention on the product page:

30000pps / 400ppr * 8mm = 600 mm/s

We tested this out with a stepper motor and a Tic T249 here and found the following motor setting worked for us (in half-step mode), so you might try them out. However, the supply voltage could have a strong effect, so if you have access to a higher voltage supply (e.g. 18-24V), I would recommend trying that out, too.

- Patrick

Thanks, Patrick,

Yes, with the 28cm-shaft motor, I was able to get that 600mm/s consistently when I had the lock collar on originally. And the 38cm-shaft was doing much worse.

Thanks for the suggestions! I’ll give them a try.

What voltage were you using for your testing?

I could certainly get a higher voltage supply, but I was trying to utilize a single supply for the arduino, roboclaw, and T249’s. Stepping up above 12 would mean needing a separate supply for the arduino, or another component to do a step down voltage, or direct feeding the arduino 5V pin from T249 or Roboclaw (while bypassing some protection circuitry). I was looking for the most robust & simple system possible, so I opted for 12V. I understand that limits the available torque and speed, but as long as I can get rates close to what the product page stated, that’s more than enough for me.

I appreciate all the help!

We tested our setup with 12V , but we saw a noticeable improvement when we bumped up to even 14V.

I would definitely advise you to play around with those settings before changing your system, but if you do decide to try a higher voltage and only use one power supply for your system, my leading suggestion would be to use a supply in the 18V-24V range and then use a step-down regulator to power your Arduino. You could also consider powering your Arduino from the 5V output on one of your Tics, but you should avoid doing that while the Arduino is connected to USB or powered through an external supply (such as the barrel jack).

- Patrick