I’ve written about the encoder code here: solderspot.wordpress.com/2014/01 … r-wallbot/

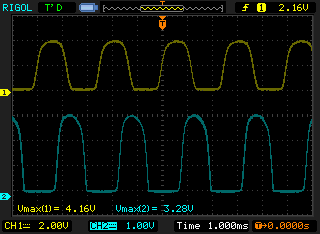

Basically it’s a high frequency interrupt routine that samples the inputs and updates a tick counter.

For the Zumo bot I’m also using the interrupt to drive the motor PWM signals. Here is the code:

/ Copyright (c) 2014, Solder Spot

// All rights reserved.

// See license.txt

#if USE_ENCODERS

#define TICK_HZ 16000L

#define CYCLE_HZ 250L

#define CYCLE_TICKS (TICK_HZ/CYCLE_HZ)

//----------------------------------------

//

//----------------------------------------

// encoder data

volatile int16_t en_lft_ticks = 0;

volatile int16_t en_rht_ticks = 0;

volatile uint16_t en_counter = 0;

volatile bool en_error = false;

char en_lApin;

char en_lBpin;

char en_rApin;

char en_rBpin;

// motor data

// each tick is 62.5 usec

// 64 ticks per cycle

struct MotorData

{

char on_ticks;

volatile bool on;

volatile char ticks_left;

char pin;

};

MotorData x_motor[2];

void init_motor( MotorData *m, char pin );

void update_motor( MotorData *m );

//----------------------------------------

//

//----------------------------------------

void setup_encoder( char lftPinA, char lftPinB, char rhtPinA, char rhtPinB )

{

en_init_pin( &en_lApin, lftPinA);

en_init_pin( &en_lBpin, lftPinB);

en_init_pin( &en_rApin, rhtPinA);

en_init_pin( &en_rBpin, rhtPinB);

init_motor( &x_motor[LEFT], 10 );

init_motor( &x_motor[RIGHT], 9 );

cli();

// set timer2 interrupt at 16000 Hz

// we are assuming a clk speed of 16MHz

TCCR2A = 0;

TCCR2B = 0;

TCNT2 = 0;

OCR2A = 124;

TCCR2A |= (1 << WGM21);

TCCR2B |= (1 << CS21);

TIMSK2 |= (1 << OCIE2A);

sei();

}

//----------------------------------------

//

//----------------------------------------

void en_init_pin( char *pin, char value)

{

*pin = value;

pinMode(value, INPUT);

digitalWrite( value, LOW);

}

//----------------------------------------

//

//----------------------------------------

bool get_ticks_since_last( int16_t *lft, int16_t *rht, uint16_t *ms )

{

cli();

*lft = en_lft_ticks;

*rht = en_rht_ticks;

*ms = en_counter>>4;

en_lft_ticks = en_rht_ticks = en_counter = 0;

char error = en_error;

en_error = false;

sei();

return !error;

}

//----------------------------------------

//

//----------------------------------------

void clear_ticks()

{

cli();

en_lft_ticks = en_rht_ticks = en_counter = 0;

en_error = false;

sei();

}

//----------------------------------------

//

//----------------------------------------

ISR(TIMER2_COMPA_vect)

{

en_counter++;

static char lastLA = 0;

static char lastLB = 0;

static char lastRA = 0;

static char lastRB = 0;

en_process(en_lApin, en_lBpin, &lastLA, &lastLB, &en_lft_ticks);

en_process(en_rApin, en_rBpin, &lastRA, &lastRB, &en_rht_ticks);

update_motor( &x_motor[LEFT] );

update_motor( &x_motor[RIGHT] );

}

//----------------------------------------

//

//----------------------------------------

void en_process( char Apin, char Bpin, char *lastA, char *lastB, volatile int16_t *ticks )

{

char A = (digitalRead( Apin) == HIGH) ? 1 : 0;

char B = (digitalRead( Bpin) == HIGH) ? 1 : 0;

char lA = *lastA;

char lB = *lastB;

char dA = A!=lA;

char dB = B!=lB;

if( dA && dB )

{

// both should not change at the same time

en_error = true;

}

else if ( dA || dB )

{

if (A^lB)

{

*ticks += 1;

}

else if(B^lA)

{

*ticks -= 1;

}

}

*lastA = A;

*lastB = B;

}

void init_motor( MotorData *m, char pin )

{

m->on_ticks = 0;

m->on = false;

m->ticks_left = CYCLE_TICKS;

m->pin = pin;

}

void set_motor( int index, char level )

{

x_motor[index].on_ticks = level;

}

void update_motor( MotorData *m )

{

if ( --(m->ticks_left) < 0 )

{

if ( m->on )

{

// turn off?

m->on = !(m->ticks_left = CYCLE_TICKS - m->on_ticks);

if( !m->on )

{

digitalWrite( m->pin, LOW );

}

}

else

{

// turn on?

m->on = (m->ticks_left = m->on_ticks) != 0;

if( m->on )

{

digitalWrite( m->pin, HIGH );

}

}

}

}

Once I go above 1KHz then servo and sensor functions get messed up as I assume their timings get thrown off.

I’m actually solutioning this by offloading the sensor and servo logic to another microcontroller, an ATtiny85, and controlling it through the I2C bus. Still debugging it all but getting close to being complete. I’ll post about the final build when it’s done.

Thanks for the followup.