Hi!

I am using a TIC T500 to control a Portescap Linear Stepper Motor 20DAM10D1B-L with 1/8th microsteps. I have currently removed any load on the actuator.

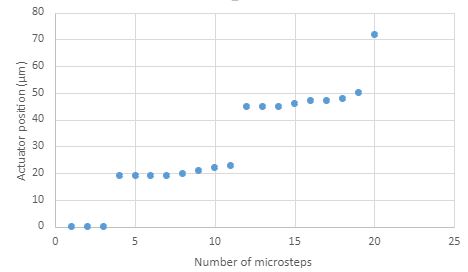

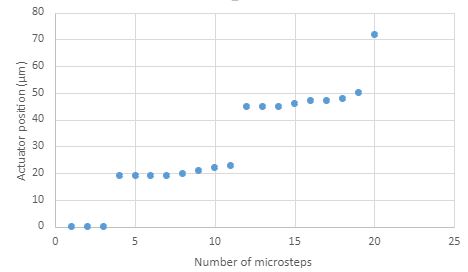

I have remarked that the microsteping doesn’t work: the motor almost doesn’t move for the seven first microsteps, then moves by one step for the last microstep.

Can you explain me how to solve this?

Additional information:

-

The motor position (full step size: 25.4µm) as a function of the microstep is given in next figure.

-

The controller is supplied with 5.5V, 2600mA. The motor requires 5V and 350mA.

-

The config file of the controller is here:

tic_settings_1d8th_microscteps_343mA.txt (1.2 KB)

Thanks in advance!

I think you’d better post your circuit diagram or a close photo of your wiring.

Hello.

From your thread title, it sounds like you suspect the Tic might be missing microsteps, but behavior like this is usually caused by the incremental torque of a motor’s microstep being unable to overcome the motor’s friction and detent torque (i.e. the motor is usually the limiting factor, not the stepper driver or controller). If you are still in doubt about the Tic, one way you could confirm that the controller is microstepping correctly is by looking at some of its outputs with an oscilloscope. The easiest way to check the behavior is with a current probe (if you happen to have access to one) but you can also look at the duty cycle of the output voltage at different microsteps.

Some options you could try to improve those results are:

- Make sure your current limit is set to the rated current for your motor. (It looks like that should be 350 mA for your motor, so you are probably fine. However, the nominal voltage, resistance, and current specs listed for your motor at the link you sent do not seem to align with Ohm’s law; you might also try a lower current limit like 250 mA just to see if it makes any difference.)

- Increase the supply voltage if you are working with high step rates. (By using a higher voltage along with active current limiting, the current is able to ramp up faster which helps ensure the motor does not skip steps at high speeds.)

- Decrease the supply voltage if you are mainly working with low step rates. (That might improve driver’s ability to limit the microstepping current more accurately.)

- With other stepper motor drivers and controllers, you could try different decay mode settings. (The decay mode on the Tic T500 is not configurable; it is selected automatically by the driver IC.)

I am not sure what you are trying to do with your motor, but another option might be to reduce the acceleration and deceleration rates on your Tic, which will usually help generate smoother motion and increase the maximum step rates you can reach. However, if your goal with microstepping is to make your stepper motor’s position control more precise, please keep in mind that microstepping is typically not very good solution for that. Here is an article with more details about that. Adding some mechanical speed reduction, such as a gearbox, is usually a better solution for increasing stepper motor position accuracy.

- Patrick