Hello,

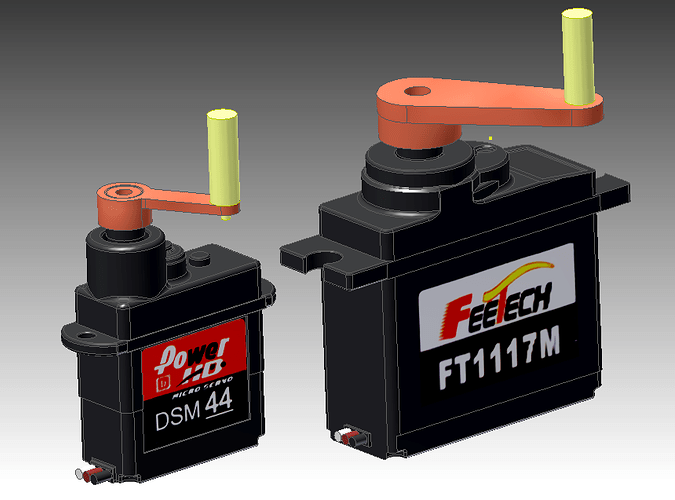

I’m using Power HD High-Speed Digital Micro Servo DSM44, which is 3.5 mm diameter 20T teeth gear.

I’m trying to find metal horn for this motor, to add metal pin with screw on this arm, to get this kind of hardware in result, as shown with my 3D models for particular purchased servos:

This example shows only the desired specific principle of attachment of pin with arm (in this case with own hardware models) of particular motors, Instead thread attachment, which seems only possible way with default plastic hardware included with DSM44, but not suitable in my particular case.

Most horns I’ve found on internet is 15, 23, 24, 25 teeth, then diameter also should be wider. I can’t figure out, how to choose adjustable or compatible aluminum arm for particular motor, from 15-30 mm length, and able to be fixed on 3.5 diameter gear with 20T. It seems impossible to find metal hardware especially for DSM44

I found number of different hardware, but I’m not sure, which one would be appropriate for DSM44, some of them 3mm diameter, but 25T, it is also not clear if 3mm diameter hole will match 3mm gear, even if it is adjustable:

- SWB 1.5″ Half Servo Arm 3mm (Futaba)

- 25mm CNC Double Lock Servo Arm, 3mm Holes with M3 CNC Clevis - Futaba by Intairco IAC-620F-C

- Heavy Duty 25T Aluminum Servo Arm (Futaba)

- JIUWU 5PCS 25T M3 Metal RC Servo Arm Horn for Futaba Savox Xcore HL HSP HD

- 2PCS CNC Aluminum Servo Horn Arm 4mm/4.76mm EMAX Servo Shaft Oppresive Clamp Horn Arm ZENOAH Carburetor Throttle Rocker Arm

- 15mm Single Hole 25T Teeth Tooth Steering Half Servo Arm Horn For 1/8 1/10 RC Car Boat FUTABA/SANWA/TACTIC/ACOMS/TAMIYA/AITEC

- K-power JB2006 CNC 20T servo arm

- ALIGN D6EF Metal Servo Horn For Align Mini/Standard Servo

- Rc Model 24t Metal Servo Arm Horn For Remote Control Cars CJG

- X8 Metal Middle Horn Set

- DS6125 Metal Horns

- RCmall 6pcs CNC Servo Horn Arm Aluminum 25T For Futaba Standard Servos 25T Blue Xcore

Also I’m using FEETECH Mini Servo FT1117M which is 25T 6 mm. It seems easier to find hardware for this motor, and I hope this horns should be appropriate, because it is most popular 25T, but anyway, I’m not sure if there is a same diameter of gear hole:

- Apex RC Products 25T Futaba Red Aluminum Dual Clamping Servo Horn

- Axial AX30836 Aluminum Servo Horn 25T

Need your help to figure out, how properly choose suitable adjustable or compatible aluminum horns for this two types of servo from lists given above or maybe any other, to not order the wrong hardware for the number of particular servo motors used in my project.

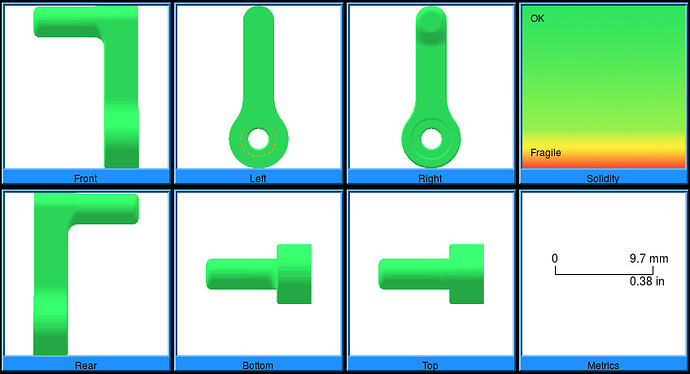

Otherwise, the only way I see is to order 3D printing for desired arm. Most cheap would be cost $7 for one unit SLS (Plastic) Nylon PA12 100-120 and $18 with Binder Jetting (Metal) Steel/Bronze 420SS/BR, for example with Sculpteo online 3D printing service.

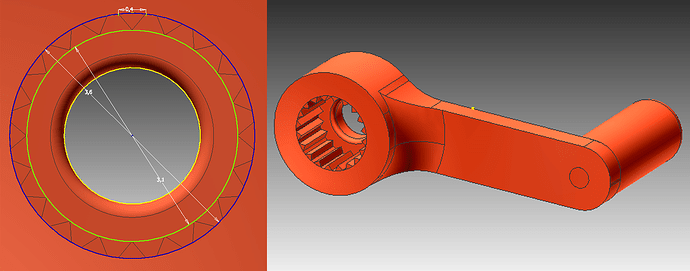

I don’t have electronic digital vernier caliper, so that’s how I managed to measure sizes with usual tool:

Teeth width: 0.6 mm

Teeth peak diameter: 3 mm

Teeth base diameter: 3.5 mm

Teeth number: 20

Here is my model sizes for solid print, in this case plastic also may be useful, because problem is that it is not possible to attach such tiny shift to DSM44 arm with 1 mm hole, so it’s possible not to use metal, but in both cases, I’m not sure about combine gear with 3D printed arm teeth, considering the behavior of such materials and very small size, if they will connect to each other with given sizes, will not get stuck or stagger:

Teeth width: 0.4 mm

Teeth peak diameter: 3.1 mm

Teeth base diameter: 3.6 mm

Teeth number: 20

I can’t find scheme for this particular hardware, to not make a mistake:

Any guide, advice or example would be very helpful