Hello, Derrill

Sorry for very late replay to your last answer.

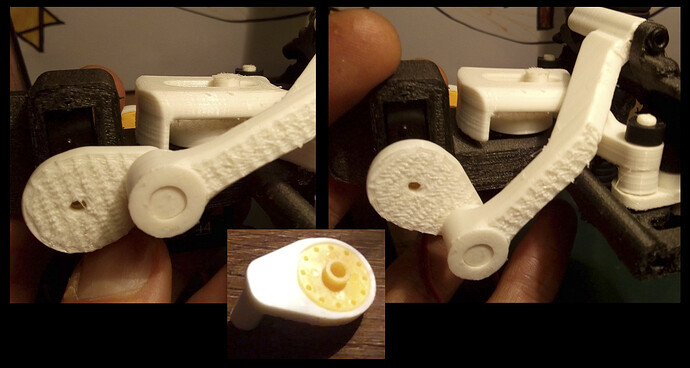

After number of successful testing with new DSM44, purchased almost half year ago this particular assembly was left for a while, device wasn’t used all this time.

Today I’ve tried to use it, but same hаppend very soon after number of sessions, one of the new servos went bad again.

Motor horn never reaches a physical limit anywhere in the assembly for sure, acceleration mass is small, mechanism moves very easily with no resistance or weight load.

SERVOMIN/MAX are defined with 160 to 500, furthermore serial event operates in narrower range

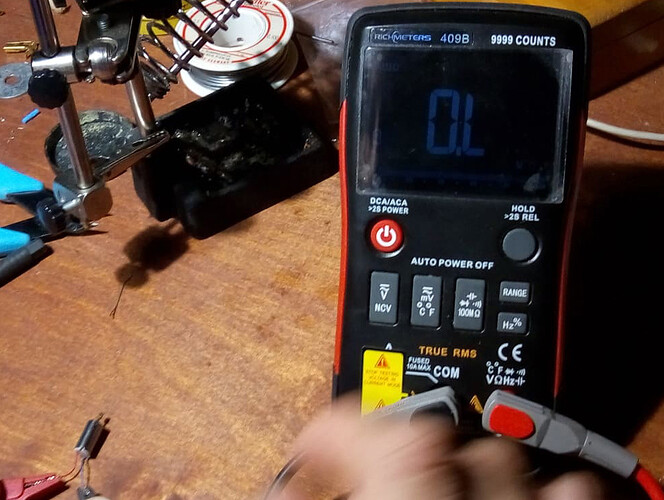

Something destroys motors, I have checked power wires of new damaged device, motor receives voltage, but motor does not moves anymore.

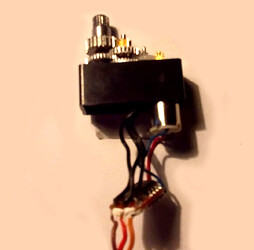

I’ve different project, which uses same devices (controller, same shield or driver, power adapter), and it was never happened with it.

DSM44 is small, fast, powerful, but by some unknown reason does not works for me, and I’m not sure how to find reason.

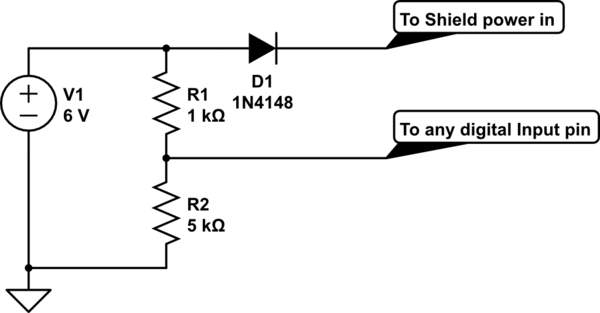

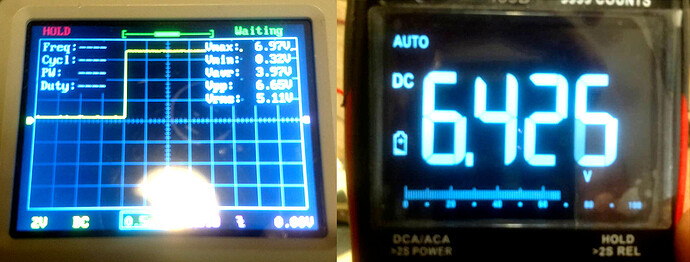

I can’t determine what the problem is with this 6V 8A power supply, but I almost sure that it happens when I plug power wire before plug of controller USB to PC, but checking of power plug moment does not shows any anomalies and controller setup() contains only: Serial.begin(9600); pwm.begin(); pwm.setPWMFreq(60); delay(10); in case of sending value to PWM first it goes through power divider condition, and this affects only DSM44.

I’m not sure how to check power supply other way and as I’ve said this same power supply works for another assembly with different motors. So, the only advice I’m trying to find now is a suitable device which will cover most of specifics required for my project:

-

Speed: No less 0.07 sec/60° with 6V

-

Power: Torque no less 1.5 kg cm with 6V

-

It does not requires get feedback, as if I use smart servo, but must be digital, because degree position should operate in short ranges with high speed, so quick response, fast acceleration and accuracy is important

-

Small size: from 20x9x26 or less to 35x12x30 plus/minus 1-5mm max

-

Must be a quite, silent as much it is possible (less important since it is difficult find a servo motor without noise)

-

Must be secure for not constant, but intense work processing of serial events

-

Control method uses Arduino Uno or Due and Adafruit Servo Shield or Driver, 6V 8A power supply, sanding of PWM degree value via serial port from C# desktop application, so controller sketch contains only receiver conditional function per each unit

Here is some ideas, that I try to understand and figure out what could be the best choice in my case.

To find suitable servo is not easy, it must be fast, powerful, small and secure, DSM44 is only motor I found by size, speed and power, but it fails for me.

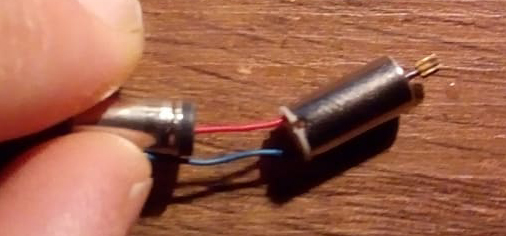

I’m not sure about Brush Servo Motor and Brushless difference with my requirements regarding safety, maybe I should use Brushless motors.

As variant if it is possible controlling of DC motors, I’m not sure about correct technique in this case, maybe I’ve to use somehow absolute of rotary encoder for this task, because in particular project gear fixing in position is not as important as start with initial position each time with controller setup() or desktop app load. If the pins are not fixed, I can move the parts manually, since in my mechanism suspended parts are controlled by horizontal shift, mobility is even good, but the loss of position after a reboot will lead to the loss of positions due incorrect start. In real world brushless DC able to control steps is a stepper motor, I’ve tried Stepper Motor: Bipolar, 200 Steps/Rev, 20×30mm, 3.9V, 0.6 A/Phase with A4988 driver , but it seems that the stepper is not quite suitable device for particular project by number of reasons, it is too big if enough powerful, it requires drivers, switch limits, which is extra in such small assembly space.

Arduino PID based DC motor position control system must be close to what I’m trying to get, but I can’t find out with correct motor by size, speed and power and suitable compact device to control multiple motors in assembly.

Another idea ClearPath Servo Motor in terms of quietness, however, the control method as available size of the motors is not entirely obvious to me yet.

Also I think about high voltage motor control if it can lead me to solution, which can be fast, powerful and quite. Maybe I have to use some professional device, if it is possible to find something not extremely expensive for personal project, but even so, I have not yet found anything suitable by described requirements and the simplicity of my assembly for this project, perhaps because my search is not correct enough, since I am more versed in programming and mechanics, than in electronics, moreover in motors

Any advice would be helpful