That’s a fun question, I never really thought of myself as having a “Line of work”. I have worked for two University robotics labs (previously the Biorobotics lab at Carnegie Mellon University, currently the Mobile Robotics Lab at the University of Michigan), and we inevitably end up using a variety of microcontrollers.

At CMU I was working mostly with PICs, just because I came in on a project that was already using them, so we had a stock and some equipment and software, but I never got really comfortable with them. Other projects in the lab used other microcontrollers, it was basically the personal preference of whoever started up a new project.

My current lab has used mainly Motorola microcontrollers in the past, and while they are certainly more powerful, they are a lot harder to get into using, and there isn’t so much of a support community for them. On more than one occasion when we needed something done quickly, instead of trying to use an existing Motorola setup, someone would run home and grab a Basic Stamp, or a PIC, or a BOE, or a Handy Cricket, or an OOPIC, or in my case, an AVR.

Recently, we’ve been using ATMegas coupled with ATTinys more than anything else. Part of this is because I have been here longer and more of the old-timers have moved on, so its more my choice, but I’m not the only one. I think a lot of it is that they are a good and approachable balance of powerful features, free development tools, and there is a big support community.

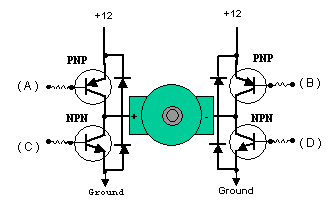

SO, if I had to run a big super-high-current motor I would probably grab either an AVR DIP chip, or an AVR development board (i.e. baby orangutan). VNH2SP30s are great when space is really tight (which is why I used them in the past, but if space wasn’t so tight, but time was, and I wasn’t worried about precise speed control I would get an RC style electronic speed controller, like for a quarter-scale electric RC car. If I had enough time and ample space I would rig a bunch of big TO-220 package discrete transistors into an h-bridge arrangement, since to some extent you can always increase your power capacity by adding more transistors in parallel.

One really nice thing about AVRs is being able to program them in-system without dedicating those pins to programming. Development boards come with programming headers, and you can build one of them into your own board, but more often than that I will make a programmer adapter out of a “chip clip,” which will clip onto and make contact with the exposed pins of a DIP or SOIC chip. You can in-system-program some PICs, but I think you have to leave those pins dedicated for programming, or if you switch them to other uses you need a 12V programmer to switch them back. Anyway, I never bothered. In general you can double-use the AVR programming pins as outputs, and in some cases as inputs, without a problem.

Anyway, at the project (not product) level there’s nothing wrong with the setup you have now, especially since you know how to program the PIC. A lot of it boils down to personal preference, and resistance to change.

-Adam