Hello,

this is my first post, I wrote in the Arduino forum and they suggested me to write here. ![]()

For a project I have to: drive one (several if it works) Peltier (TEC) element. Running the same face hot or cold, according to user selection. Also with the ability to set the desired temperature (hot or cold).

Therefore my objective is: to drive a TEC element, maintaining the ability to inverse the polarity. Using cost-effective components because it’s a really low budget project.

Components: for a technical reason, I need to use this very small peltier. Rated 0.8v 3.2A.

Looking for a cost-effective solution for driving a TEC with Arduino, I found several posts on google, suggesting a motor h-bridge.

The problem is that usually the motor drivers are rated for higher VmotorIn voltage, >3 volts.

The only viable and cost-effective solution I found is this small driver from Pololu.

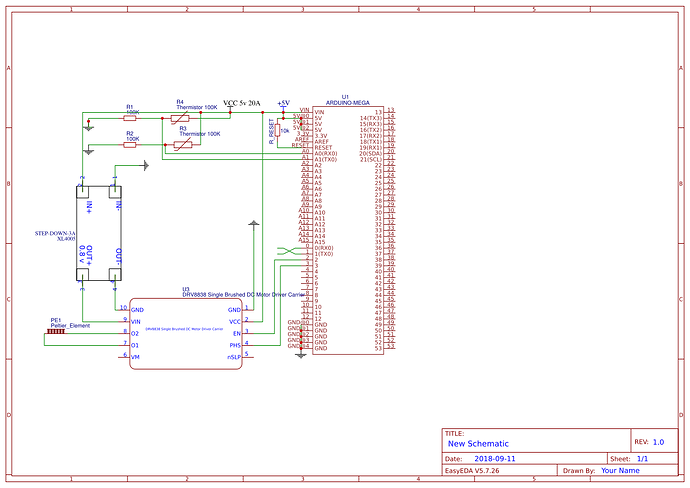

I built the circuit, and it actually worked. (diagram attached)

But there are several problems:

- I have to turn up the voltage from 0.8v to 1.5v at the driver V motor In. Otherwise, I have no response from the TEC at all.

- Nonetheless, I have a significant voltage drop on the TEC. I supply to the driver 1.5v but I measure 0.4v on the TEC terminals.

The TEC works, it reaches the temperature, I can switch the polarity and so on.

But I do not understand the voltage drop, and the driver runs very hot.

I would also like to find a different solution because right now I’m driving the TEC only a 1.7A (driver internal limit)

While I could safely push up to 75% of the power (let’s say 2.5A).

So my question are:

- how can I drive a TEC element rated at 0.8v?

- How can I improve my circuit with low-cost components?

- Can I use PID and PWM with this TEC/circuit? In other h-bridge solution, I found PID and PWM a 200khz is usually implemented.

In the Arduino forum, they suggested me to use two drivers in parallel. I run this solution and it works more stable, nonetheless, I still have the voltage drop and the overheating.

I saw your DRV8835 Dual Motor Driver Carrier, can it work better in substitution for the two parallel drivers I have now?

will it avoid overheating?

Otherwise would you please suggest me a better a solution to drive these TECs?

Thank you all very much,

Paula