Hi, I’m Nathan. You may remember me from such posts as Logic Level Shifter for reading motor encoders and VNH5019 Additional Capacitor. I’m currently testing out the encoders on my 30:1 Metal Gearmotor 37Dx68L.

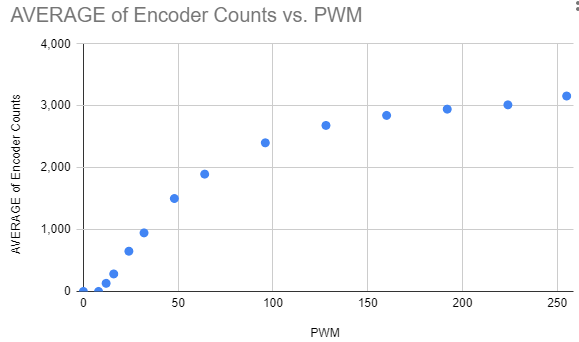

I wrote a test program to compare the PWM value against the motor speed measured by the encoder. I was expecting a linear relationship, but I found a logarithmic looking one. Below is a graph of my results, showing the average encoder counts per second against the Arduino PWM value (0-255).

My questions are:

- Is my expectation of a linear relationship correct, or is the nonlinear relationship as expected?

- If my linear expectation is correct, can anyone see a problem with my test?

- Why is the top speed ~3150 counts per second instead of ~2640?

Any help or advice would be greatly appreciated.

I have the following connections between my components and the Arduino Nano 33 IoT microcontroller:

- D5 → IN1 on VNH5019

- D7 → IN2 on VNH5019

- D6 → PWM on VNH5019

- 3V3 → VDD on VNH5019

- GND → GND on VNH5019

- 5V → Encoder Vcc on motor

- GND → Encoder GND on motor

- D2 → Encoder A output on motor (via logic level shifter)

VIN on the VNH5019 is connected to a 3S 18650 battery, which is currently outputting 12.3V. As per my previous post, I measured 12V across the additional capacitor on the VNH5019.

![]() Note that I also tried replacing the logic level shifter with a 1k/2.2k resistor voltage divider, but I got the same results.

Note that I also tried replacing the logic level shifter with a 1k/2.2k resistor voltage divider, but I got the same results.

My Arduino code is below:

const int ENCODER_A = 2;

const int ENCODER_B = 3;

const int IN1 = 5;

const int IN2 = 7;

const int PWM = 6;

const int MOTOR_SPEEDS[] = { 0, 8, 12, 16, 24, 32, 48, 64, 96, 128, 160, 192, 224, 255 };

const int MOTOR_SPEEDS_LENGTH = 14;

const int LOOP_MICROS = 1000000;

volatile int pulseCount = 0;

long loopEndTime = 0;

long measurementTime = 0;

int speedIndex = 0;

int speedLoopCount = 0;

void setup() {

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(PWM, OUTPUT);

Serial.begin(2000000);

while (!Serial);

pinMode(ENCODER_A, INPUT_PULLUP);

pinMode(ENCODER_B, INPUT_PULLUP);

attachInterrupt(digitalPinToInterrupt(ENCODER_A), encoderPulse, RISING);

measurementTime = micros();

loopEndTime = micros() + LOOP_MICROS;

}

void encoderPulse() {

pulseCount++;

}

void loop() {

if (speedIndex >= MOTOR_SPEEDS_LENGTH) {

analogWrite(PWM, 0);

while (true);

}

int speed = MOTOR_SPEEDS[speedIndex];

speedLoopCount++;

if (speedLoopCount >= 15) {

speedIndex++;

speedLoopCount = 0;

}

//control speed

analogWrite(PWM, speed);

//control direction

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

noInterrupts();

long now = micros();

int pulseCountValue = pulseCount;

pulseCount = 0;

interrupts();

long measurementInterval = now - measurementTime;

measurementTime = now;

Serial.print(speed);

Serial.print(",");

Serial.print(measurementInterval);

Serial.print(",");

Serial.println(pulseCountValue);

while(loopEndTime > micros());

loopEndTime += LOOP_MICROS;

}