I have a few quick questions for you first, just to get us on the same page:

What kind of microcontroller are you using to command your micro dual serial servo controller (lets call it the uDSMC for short)?

What is your power source for the motors (1.8V-9V)?

What is your power source for the uDSMC logic supply (2.5V-5.5V)?

What connections have you made between the uDSMC and your micro controller? Between the uDSMC and your power sources?

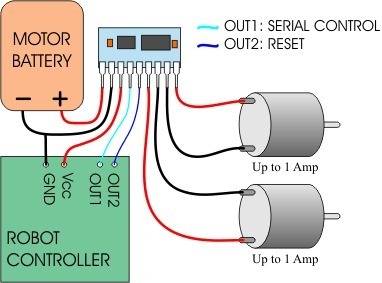

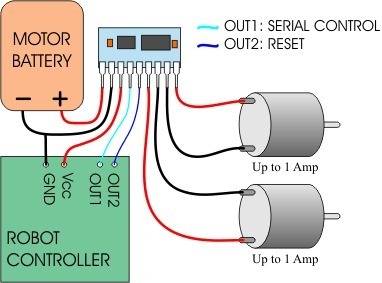

And just for good measure, lets cover the basics. You’ll want to connect up your motor controller like in the manual:

Pin 1 is the motor power supply, and Pin 2 is the common ground. The motor power source doesn’t necessarily have to be the same as your microcontroller’s power source, but both grounds do need to be connected.

Pin 3 is the logic supply pin for power to run the electronics on the uDSMC. It should most definitely be separate from the motor power, and be between 2.5V and 5.5V. You can probably steel power from your microcontroller’s battery or regulated supply.

Pin 4 is the serial input pin, which should be connected to the serial TX line of your microcontroller. You want to send TTL-level, non-inverted 8N1 (8-bit, no parity, one stop bit) serial bytes to the uDSMC. We’ll get into the command protocol in a second. The uDSMC will automatically detect your serial baud rate (from 1200 to 19200 bps) when you send the first byte. It expects to keep receiving bytes at this baud rate, so if you want to change your baud rate you have to reset the uDSMC first.

Pin 5 is the reset pin, which is maybe a little counter-intuitive. For your motor controller to function at all, this pin has to be pulled up to the logic supply voltage. As shown in the wiring diagram above, you can connect it to a digital output pin on your microcontroller and bring that pin high to start up the uDSMC (and low to reset it if/when you want to). You can also permanently pull the reset pin high by connecting it through a resistor (around 4.7 Kohm) to your logic supply voltage.

Finally, pins 6 and 7 go to one motor, and pins 8 and 9 go to the other.

Then you have to figure out what bytes to send according to the Pololu serial control protocol. It helps to understand binary, decimal and hex bases, but it’s not critical.

Basically every command must start with the special start byte: the number 128 (which is 0x80 in hex, or 0b10000000 in binary). In binary, 128 has 1 high bit, followed by 7 low bits, and it is the only number with 1 as it’s high bit allowed by the protocol (it’s special, so the uDSMC can recognize it as the start of a new command). So, all other numbers in the protocol will be between zero and 127.

The number after the start byte is the device ID, which is 0 for Pololu motor controllers. The section that has to do with configuring the motor controller using device ID 2 comes first in the manual, but that’s more complicated and you only need to do that if you want to use multiple motor controllers on the same serial line, or to switch your controller into single motor mode. You don’t want to do either of these, so let’s just use the default configuration, which means the device ID byte should be 0.

The next number is the motor number and direction together. As I mentioned above, the motor numbers are programmable so that you can have many controllers on the same serial line, but all controllers will respond to the motor numbers 0 and 1, so lets use those. The formula for this byte is (motor number)*2 for reverse, and (motor number)*2+1 for forward. So the byte values you want to consider are:

Motor 0 reverse: 0

Motor 0 forward: 1

Motor 1 reverse: 2

Motor 1 forward: 3

Finally, the last byte is a speed command, from 0 to 127. As you would expect, 0 means stop, while 127 means full speed in the direction you specified in the last byte. For speeds in between, try numbers in between.

So, to sum up, in each command you want to send:

128 - Start Byte

0 - Device ID

0, 1, 2, or 3 - motor number and direction

0-127 - motor speed

If you send two commands one right after the other the motors will start up at almost exactly the same time, and you won’t even be able to tell the difference.

So, what still doesn’t make sense?

-Adam

and need some assistance getting it running… I have read and re-read the book about 10 times to try and make sense of if but it is very confusing to me and i need to know how the microcontroller works so i may program my microcontroller correctly to send out the correct serial signal.

and need some assistance getting it running… I have read and re-read the book about 10 times to try and make sense of if but it is very confusing to me and i need to know how the microcontroller works so i may program my microcontroller correctly to send out the correct serial signal.