I am making a fully functioning miniature elevator and need a little help. The mechanics of the door and lift system are easy but the motor control of the door is not. All I really need is a DC motor to run in one direction when a momentary button (SW1) is pressed and to stop at a limit point. Then when SW1 is pressed again the motor reverses direction and moves to a second limit point and stops. Push button - doors opens, push button - door closes. It seems easy enough and I started to get excited about the Simple controllers having an analog input option. It talks about use as a limit switch but when I read through the resources section I got lost quickly trying to figure out if it was possible to do what I need with these controllers.

Before I buy it I want to know if I can use it!

Anyone have some input?

Thanks so much.

Hello.

The Simple Motor Controller’s limit switch feature should work fine for you. You can configure one of the analog inputs as a “Forward Limit Switch” and the other as a “Reverse Limit Switch”. Whenever a limit switch is pressed, the SMC will stop driving the motor in the specified direction, but it will be allowed to move in the other direction. To set up an analog input channel as a limit switch, you could wire a button from the input line to GND, choose what type of limit switch it will be, check the “Enable pull-up resistor” option, uncheck the “Ignore Pot Disconnect” setting, click Apply Settings, and then click the “Learn…” button for the channel. The sections of the user’s guide that describe limit switches are here:

5.1 Input Settings

5.1.1 Configuring a Limit or Kill Switch

However, you would need to get another microcontroller to process the button presses, keep track of the current state of your door, and send serial commands to the Simple Motor Controller’s RX line. Do you already have a microcontroller that you are familiar with? If you want to learn something new, we sell a number of programmable controllers that can all do the job: Mini Maestro 12-channel Servo Controller, Wixel, mbed, Baby Orangutan, or Arduino.

–David

Thanks for the reply. I felt like a motor controller and then a microcontroller is a lot of wasted silicon for what I need to do! Not to mention the learning curve - which I don’t mind, but I am doing this for a client and want to be able to troubleshoot the design if there are problems down the road.

Since there were no microcontrollers back in the day but there were elevators, I figured there was a solid state way of doing it. With a bit of head scratching I figured out a way to do all of what needs to happen with two DPDT relays.

I plan to play with microcontrollers and add them to my tinkering repertoire. When I do I will certainly buy what I need from your site.

Thanks again.

Ok. Well it sounds like an interesting project. I’d be interested in hearing how you plan to implement the pushbutton with your DPDT relays, and also it would be great to see some photos or a video when the project is complete. Good luck!

–David

Sorry it took so long to show you this David.

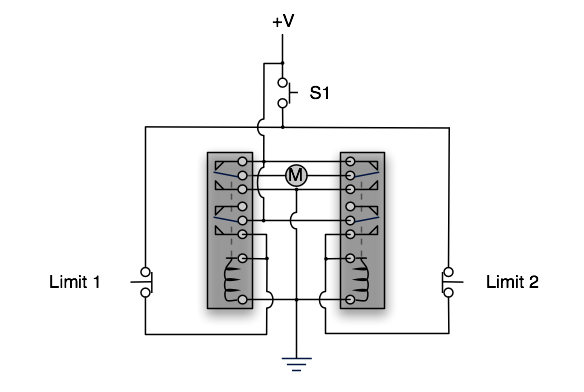

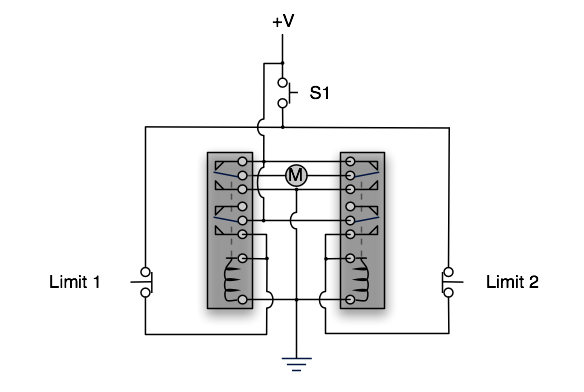

The limit switches are activated by the carriage at either end of a linear run (rack and pinion). When S1 is pressed, whichever relay is able to be energized latches itself and runs the motor in a given direction until the limit switch on the other end of the run is activated. Therefore, no constant current waiting for input and the whole thing just uses those relays and a few push button switches!

This is a bit off topic, but do you have any photos or drawings of your elevator mechanism? It just happen to need a vertical lift feature for a project I’m working on, so I’d like to see what other people have done.

By the way, I was using a microswitch to detect index marks for position control, but I eventually switched to using Pololu’s QTR-1A Reflectance Sensor. It required an analog input and a bit more code to clean and debounce the signal, but an optical sensor ended up making a much cleaner mechanical design which was also easier to calibrate. It’s also totally silent – not a feature to be ignored! The click-click-click from the microswitch was getting on my nerves, which was the real motive for me to try the QTR-1A in the first place.

Thanks,

Noah

Thanks for the input Noah.

The elevator lift is being provided by a garage door opener:

sommer-opener.com/Direct-Dri … HP_p_9.htm

My carriage is attached directly to the motor housing.

Since this seems to have been popular, I will endeavor to get photos as soon as I can.