Hello from germany!

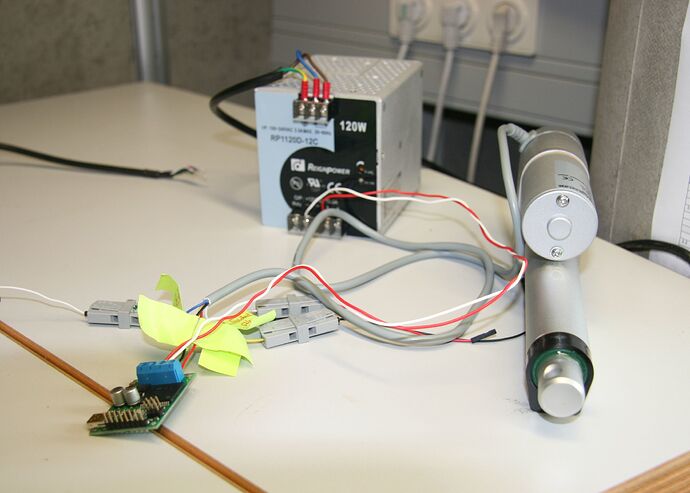

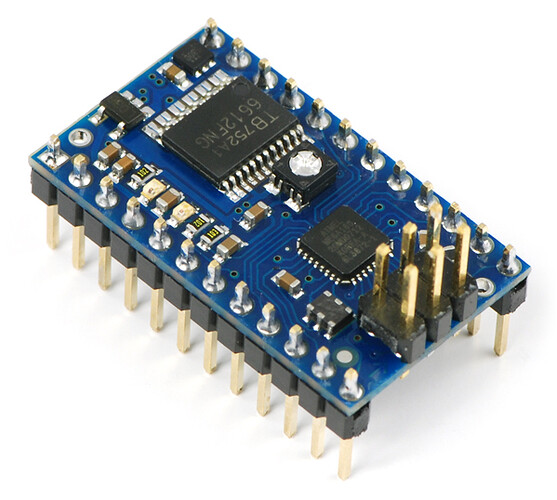

I bought a Polulu JRK 12v12 to run a linear actuator which is similar to that, which is selling here. (Link of my linear actuator is here: http://www.conrad.biz/ce/de/product/191745/Transmotec-DC-Linear-Motor-DLA-DLA-12-40-A-100-POT-IP65-16024244CR-12-VDC-Hub-Laenge-100-mm-Schubleistung-1200-N-Geschwi/1101104&ref=list

This is the same actuator but with a different gearbox (40:1) to have more force.

My powersupply is a 120 W 12V 10A supply from industry. It dropes the need 12v without a problem.

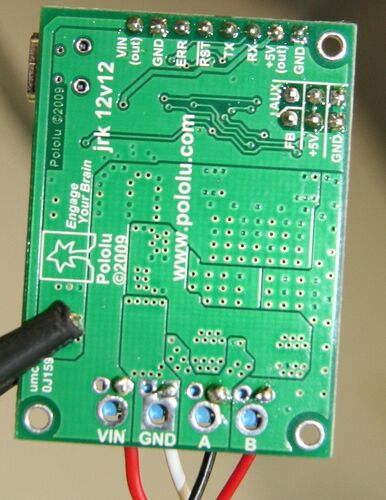

I wired plus and minus from my power supply to the JRK (VIN, GND). From the actuator i wired the black (gnd) and red (+) cable to a and b (the same as in your picture discription on LA product pages). i measured the VIN and GND voltage drop, and its 12v. Feedback is also connected.

In the configuration utility, i load the start settings as described in the product guide for the jrk. i applied every settings using the apply button. i deactivated feedback, i use serial mode with USB Dual Port.

Motorsettings: everything as default, but limited the max current to 4 A to test.

THE PROBLEM:

When i press the “target” button or the “run motor” button, nothing happends. The motor wont drive.

During the “run motor” command, the error status shows: 0x0000 and in the error tab nothing is shown.

When i clicked “stop motor” then i got an error: 0x0001. I think this is okay, because its the bit to stop the motor?

several times i got errors on 0x0002 and 0x0004. But normaly not!

When the motor should be running (when button is pressed) i measured the voltage dropdown. Voltage is only 0,4V!

What happens here? What can i do to move the actuator.

i ordered the not assembley version of the jrk, so i soldered the screw terminals and pins on my self. but they are also contacted i think. could the problem be there?

I tried to connect the actuatur directly to the power supply, everything is ok. The actuatur moves.

Thank you for helping me. I can make pictures if this helps.