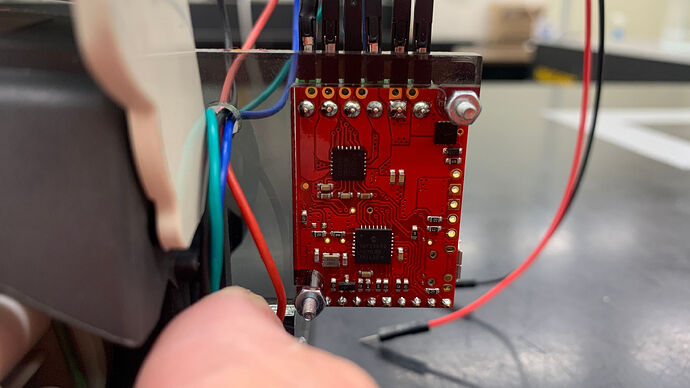

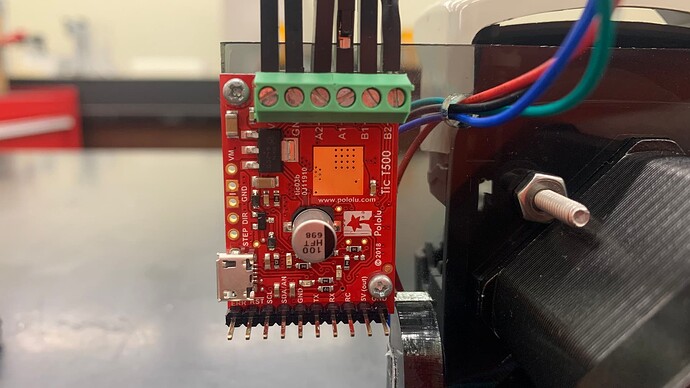

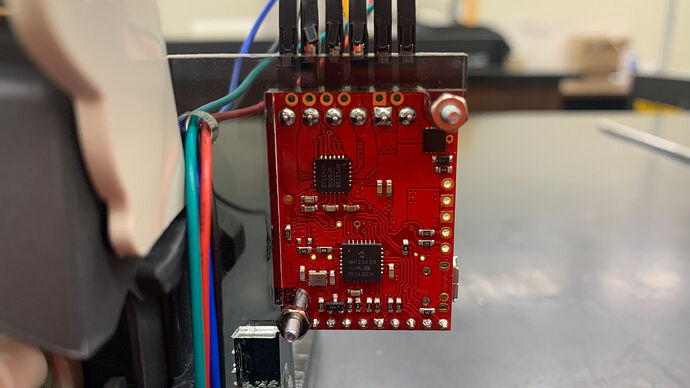

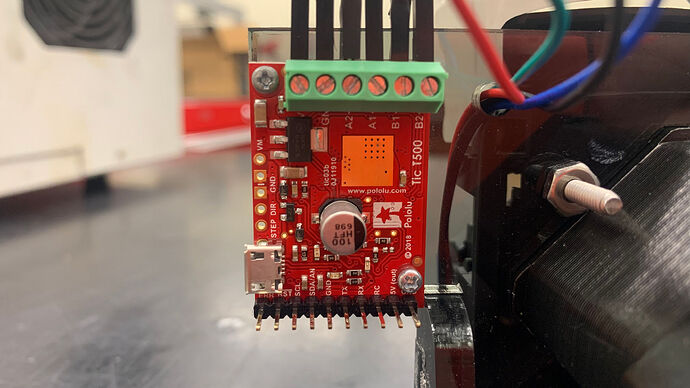

I have two identical motors run by two T500s.

As of yesterday, one of the motors started behaving erratically at part loads/speeds. Everything is fine if I run the motor at max. speed but as soon as I try to reduce it the motor starts grinding, skipping, etc.

To troubleshoot the issue I swapped the controllers between the two motors, all the wiring, power supply, and even disassembled and assembled the pumps to make sure there are no mechanical issues. The issue is always with the motor run by the same T500. The other T500 runs both motors at lower speeds without the issue.

Now, I’d like to troubleshoot the T500. The only thing I found in the docs is to issue the ticcmd --reset command but that didn’t help. What else can I do to troubleshoot the Tic?

To illustrate the problem, please see below the videos of motor behavior and setting used in each case. You can see how the performance deteriorates with reduction in speed, for both full and 1/8 step.

Tic Control Center settings file is also attached.

tic_settings.txt (1.3 KB)

I’d appreciate any help with this, as this is really destroying a time sensitive pipeline I’m currently running. Thanks!!

A) Full Step

-

Max. speed

ticcmd --resume --current 1198 --step-mode full --max-speed 13333333 --velocity 13333333

https://drive.google.com/file/d/1ofmGJvR-ekgwS2bNqUuhLOijYCKk92ty/view?usp=sharing -

3/4 max. speed

ticcmd --resume --current 1198 --step-mode full --max-speed 13333333 --velocity 9999999

https://drive.google.com/file/d/1XpXAhp7QW2jBYZQ3VaCj8uHgaxR3GECf/view?usp=sharing -

1/2 max. speed

ticcmd --resume --current 1198 --step-mode full --max-speed 13333333 --velocity 6666666

https://drive.google.com/file/d/14D5yb1Ygusi7jVe2oTd--HP0kxDL5SEB/view?usp=sharing -

1/4 max. speed

ticcmd --resume --current 1198 --step-mode full --max-speed 13333333 --velocity 3333333

https://drive.google.com/file/d/1zXlaSNCFeXFu3jyeNMgj3cq-E3I2uavy/view?usp=sharing

B) 1/8 Step

-

Max. speed

ticcmd --resume --current 1198 --step-mode 8 --max-speed 106666666 --velocity 106666666

https://drive.google.com/file/d/1I7Z-4EH_0dZr-_GpJJVXXf-2HO-8uOdd/view?usp=sharing -

3/4 max. speed

ticcmd --resume --current 1198 --step-mode 8 --max-speed 106666666 --velocity 79999999

https://drive.google.com/file/d/1tK1_kRyOybZhIL8RQnN2Q854u1nUx1hh/view?usp=sharing -

1/2 max. speed

ticcmd --resume --current 1198 --step-mode 8 --max-speed 106666666 --velocity 53333333

https://drive.google.com/file/d/1-sQogHYWci5oiT5qdixLpSwn2DKT2MjF/view?usp=sharing -

1/4 max. speed

ticcmd --resume --current 1198 --step-mode 8 --max-speed 106666666 --velocity 26666666

https://drive.google.com/file/d/1aYhL5goyJ7bi6ATVHpgxLguetiqFOHNY/view?usp=sharing