Hi, I am looking for some guidance on a prototype I am working on. I’ve been using various types of robot wheels as a rotary bow for different stringed instruments. I’ll post an example video below.

So far I’ve been using a 12v 300 mm motor with this PWM Controller from Amazon Amazon.com

I want to make a similar motorized wheel bow attached to a dowel rod so that I can hit the strings with the wheel. (here’s a sketch: https://i.imgur.com/Ckkf6jl.jpg) To do this I need to find a combination of right angle worm gear motor, a small controller and a small battery that could all be attached to a roughly 1/2" dowel about 12-15" long. Ideally it could have speed controller, either with a small thumb knob or Force Sensing Resistor. I know that FSRs can be very jumpy, so might not be the best thing for a wheel that has to have a pretty stable speed. Some kind of arduino approach might be feasible but I’m not super confident with that kind of coding.

For the motor I would prefer something small and quiet with a 3mm D-shaft. I have been putting the wheel directly on the d-shaft but if there is a better way to approach this with hubs and extensions, that would be great.

Any guidance or ideas for what parts might work here would be great. Browsing the site I get the sense that there are probably a bunch of ways to achieve this but I’m hoping not to overengineer as I focus on materials and playability.

Example of existing prototype, 3D printed pololu wheel design wrapped in synthetic horsehair

Scott Hampton on Instagram: "Workshopping a new track called “Light Inside the Body” with the new horsehair version of the Rotobow #rotobow #guitarviol #funk #viola #experimentalinstruments #hurdygurdy"

Hello.

That sounds like a really fun project, and thanks for sharing the video!

Offering assistance with project design is typically beyond the scope of our technical support, so I moved your post to a discussion category in case other might feel more inclined to weigh in here.

Unfortunately, I do not have any specific part recommendations, but here are some links to some of our product categories that might be useful:

Once you get to the point in your design process where you have specific constraints and criteria for particular components, let us know and we might be able to offer more advice.

- Patrick

Ok thanks, I’ll put together a list of components and check in here to see if it makes sense.

2 Likes

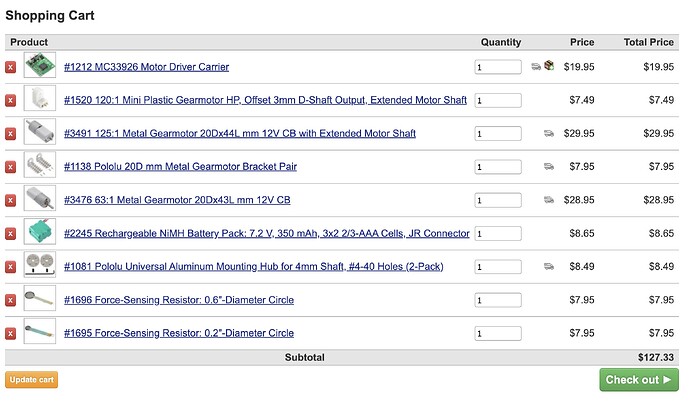

Hi Patrick, I was able to put together a rough parts list and I wanted to check in re compatibility before ordering.

In the screenshot of my shopping cart, I have a few motors that I wanted to try using with the |

#1212 MC33926 Motor Driver Carrier| and |#1696 Force-Sensing Resistor: 0.6″-Diameter Circle|

Would this combination make sense? I know that FSRs can be jumpy but I’m hoping it would be possible to smooth out with resistor and/or capacitor rather than having to go the arduino route?

Also wondering if the

#2245 Rechargeable NiMH Battery Pack: 7.2 V, 350 mAh, 3x2 2/3-AAA Cells, JR Connector would work with these motors and driver? If so can you recommend a charger for that battery pack, it seems like all the recommended chargers are discontinued?

Thanks in advance for any guidance you can provide!

Hello.

If you use the force-sensing resistor (FSR) in an appropriate voltage divider circuit, you can use it to generate an analog voltage that varies with the force applied. However, the MC33926 carrier (like our other motor driver carriers) requires digital control signals as inputs, and there is probably not a practical way to generate the required signals from an analog voltage without using some kind of microcontroller, like an Arduino. If you really want to avoid needing an Arduino, then you will need a more sophisticated motor controller that can use an analog voltage as an input, such as the Jrk G2 21v3.

Your battery selection might be okay for one of the 20D 12V motors you selected, but there are lots of factors that could affect that choice, like the minimum voltage requirements for your driver and other electronics, how long you want your system to run on a single charge, how much load you expect on the motor, etc. In general, I recommend choosing a battery with an output voltage closer to the rated voltage for your motor and higher capacity, but that will come at the cost of increased size and weight. I suggest reading through this battery capacity blog post for a more detailed discussion about that.

Unfortunately, I do not have any specific recommendations for a compatible charger. In case it helps, I searched “NiMH battery charger JR connectors” on Amazon and found several results that look like they might be okay, but I cannot vouch for any of them in particular.

- Patrick

1 Like