Hi,

I have met an interesting problem when using the Pololu 6V HP 1000:1 motor and a DRV8838 motor driver breakout. When the motor is stalled, the voltage between the driver O1 and O2 ends (at the motor end) will decrease to 3.48V and the current as 680-700mA. The power supply is a Li-Ion battery (11.1V, 2.6Ah), passing through a DC/DC buck converter, and the total output voltage is 7.2V.

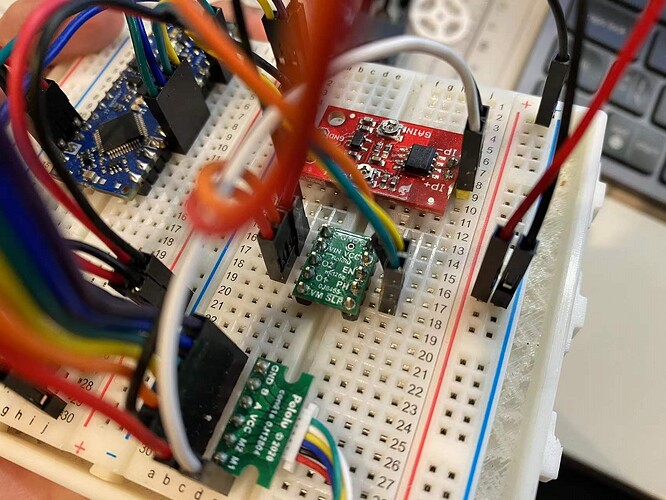

I have checked the datasheet of DRV8838 and followed the instructions listed on the webpage. The pin voltages are:

GND - common end of Arduino Nano Every GND;

VIN: Power supply (7.2V, Li-Ion);

O1&O2: Motor pins;

EN/PH: digital pins, controlled by PWM;

VM: NOT connected.

VCC: Arduino voltage output of 5V;

SLP: not connected.

The problem occurs and is exactly the same even when connecting VM as the power supply (VIN Not connected).

The programmes and components work normally and are fully functional - everything’s ok - except this problem.

I would like to know, what is/are the reasons for the voltage drop off when the motor is stalled? I would like to acquire torque as high as possible, and the motor position is controlled by Pololu magnetic encoders, so the motor should stop when it is stalled - but the torque during this moment is extremely important in my robot design.

One solution is providing a higher voltage supply (such as 11V) to overcome the reversed voltage generated when the motor is stalled. But I think there should be better solutions and seeking help.

Hello.

Before getting into why the output voltage might be decreasing, please note that stalling or overloading brushed DC gearmotors can greatly decrease their lifetimes and even result in immediate damage. Because of the high gear ratio, these 1000:1 gearmotors can easily generate enough torque to damage themselves, so you should not be stalling them. Our recommended upper limit for instantaneous torque for the 1000:1 gearbox is 2.5 kg-cm (35 oz-in), as mentioned on the motor’s product page.

As far as the output voltage dropping, one thing that stands out to me from the information you gave is that you are running the motor at 7.2V, and at that operating voltage, the motor could draw nearly 2A when stalled. What step-down regulator are you using? Can it handle that kind of current draw on the output? The minimum threshold for the DRV8838’s over-current protection is 1.9A, so it might be possible that you are seeing that as well.

However, as I mentioned at the beginning of this post, you should not be using the 1000:1 HP micro metal gearmotor at that kind of current/torque. So, if you need more torque than 2.5 kg-cm, you might consider upgrading to a larger, more powerful gearmotor like one from our 20D or 25D selection.

Brandon

1 Like

Hi Brandon,

Yes, I am aware that the motor stall may damage the motor, so I managed to increase the detection sensitivity so that the motor will stop within 500ms when detecting the stall.

As for the battery, I brought the DC/DC buck converter from Amazon (https://www.amazon.co.uk/ARCELI-Converter-Buck-Boost-Adjustable-Regulator/dp/B07MY399GQ/ref=cm_cr_arp_d_product_top?ie=UTF8), and the current can handle the current draw.

I thought the problem may be caused by the battery. The first battery I brought is a PALO 9V 650mAh from eBay, transmitting the voltage after the buck converter above. I don’t have its datasheet so I assumed the battery cannot deal with the 2A output, so I brought another Li-Ion battery with maximum current output >4A (now it should not be the problem of the battery), also transmitting through the buck converter.

Based on your advice, do you have any suggestions on replacing the buck converter? I have checked the Pololu regulator, maybe [#2575:S18V20F6]? The only problem is that I would like to control the overall size of the boards because the motor is used to drive a robotic hand finger and does not have much space inside the palm.

The 1000:1 HP micro metal gearmotors are intended for use in systems that need finer control at low speeds; they are not designed to stall. It will almost certainly destroy itself well before reaching the theoretical stall torque (your voltage dropping problem is likely the only thing stopping it from doing so right now). For reference, the 2.5 kg-cm value I mentioned in my previous post is for instantaneous loads. The extrapolated stall torque of that motor at 7.2V is nearly 6 times this limit (around 14.4 kg-cm).

I do not see documentation for that regulator that clarifies how much output current it can handle at your input voltage, so it is hard to say if it is the cause for sure. The problem might also be from using a breadboard (they are not good for high current applications and the increased resistance could be causing the voltage drop). You might try measuring the voltage before and after the regulator as well as at the input of the motor driver. If you do need a small regulator that can handle 2A when stepping down from 11.1V, you might consider the 7.5V, 2.6A Step-Down Voltage Regulator D36V28F7. However, it definitely sounds like the 1000:1 HP micro metal gearmotor is not appropriate for your application. If the 20D or 25D motors that I linked to in my previous post are not an option for you, you might consider adding some external reduction to take some load off of the gearmotor so it does not have to stall.

Brandon

Hi Brandon,

GREAT! Thank you for your help. I have ordered the D36V28F7 and S18V20F6 to do some tests.

And yes, I have added a pair of reduction gears (i=2.15) to decrease the motor speed. Let’s see what will happen next. ; )