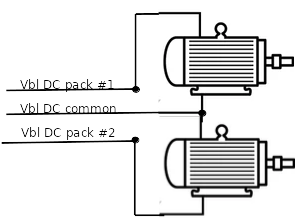

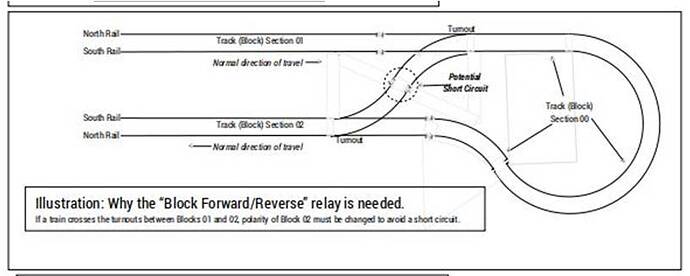

I have a model railroad which uses two power packs to provide DC voltage to two different sets of tracks. The tracks utilize a common rail system- - that is, the two packs provide up to +12 volts DC and use a common ground. Because there are two independent power packs using 117 volt AC current to provide the power, the two independent DC motors in the locomotives running on this system can be controlled separately.

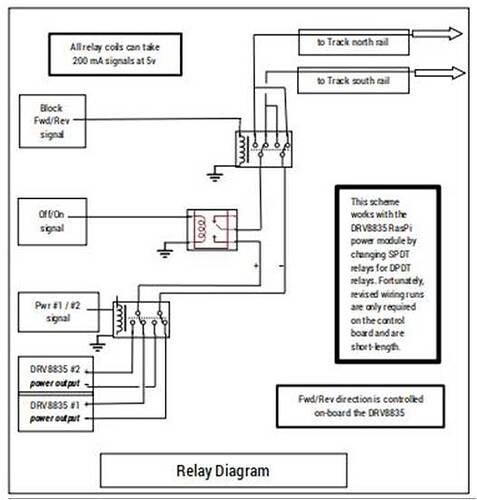

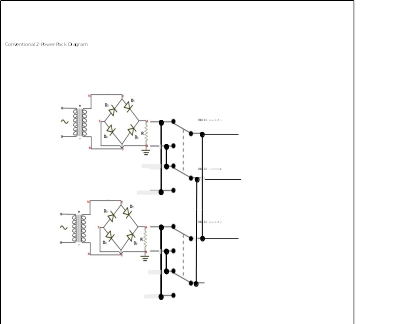

SPDT relays to select which power pack supplies which individual track section, and DPDT reversing switches for each track section, are not shown here. The above circuit works because the two transformers are isolated from each other. (Trying to use a single power pack to power both sides of the circuit results in a short circuit.)

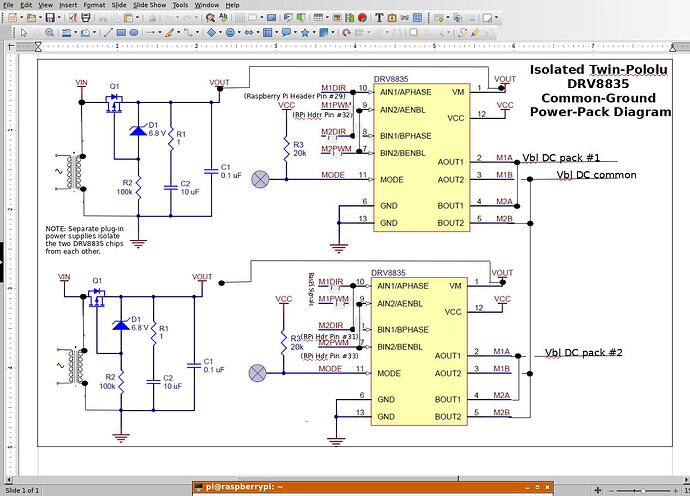

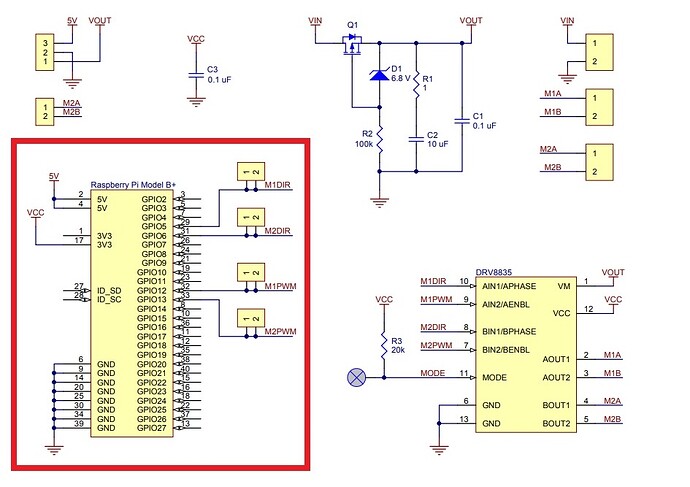

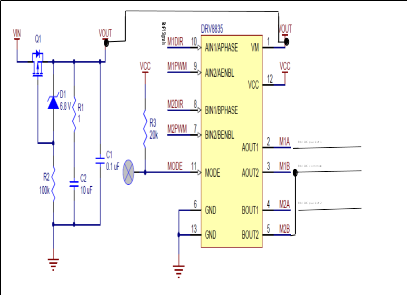

I am in the process of adding a Pololu DRV 8835 Dual Motor Driver Kit and a 9 volt DC plug-in power source to my Raspberry Pi. The computer already controls everything on my layout except the power packs. I’m concerned, though, that the common rail system may not work because the two current sources on the DRV8835 board, which go to the tracks, may not be independent. The proposed setup is as follows:

Could one or two of you electronics gurus out there give me some advice? This is “above my pay grade.”

.)

.)