Hello!

I’m running into a brick wall getting my stepper motors to move using recently purchased TB67S249FTG stepper drivers. They will occasionally give the tiniest of twitches (ex. When turned on), but otherwise the motors are locked in place.

Quick caveat: I’m a professional programmer with very little hardware experience. Parsing schematics to actual wiring takes a while if there’s not a physical picture. But I’m learning! Apologies if my terms aren’t right, just let me know and I’ll upgrade my terms.

The players:

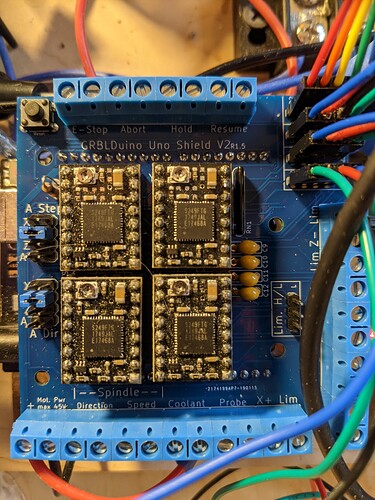

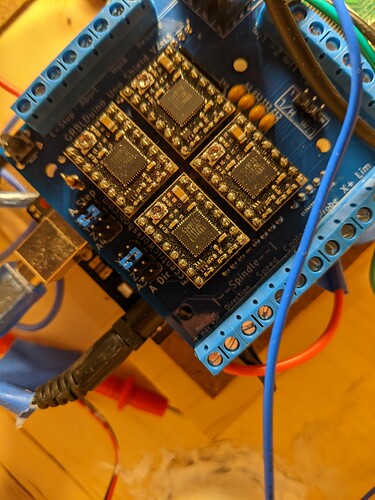

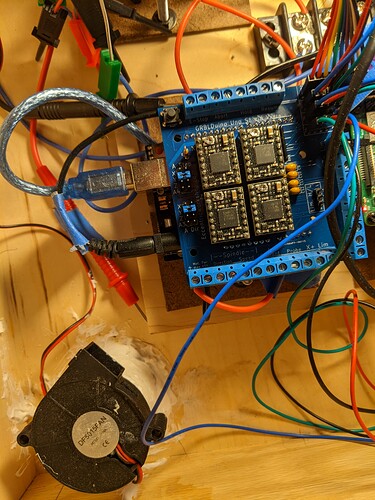

- TB67S249FTG stepper driver(s)

- STEPPERONLINE 3PCS Nema 23 CNC Stepper Motor 2.8A 179oz.in 56mm Bipolar

- Elegoo Arduino Uno

- GRBLDuino 1.1 from Eccentric Workshop running GRBL 1.1f

○ CNC Shield jumpers set for full step, I screwed up originally by having no jumper (Standby) after originally confusing DRV8845 spec with mine at the time. Whoops!

- 24v MeanWell power supply

In my software world, I’d try to rule out half the problems with a targeted diagnostic, then do the same on the result with another diagnostic, and repeat making the problem smaller until I found cause. I’m struggling to understand what those diagnostics might be in a hardware world.

So here’s what I’ve thought of so far, can someone help me fill in the gaps?

At rest, no commands sent or movement expected, multimeter voltage readings:

- VMOT Resting voltage to adjacent VMOT GND : 24V

- GND to FAULT : 5v

- GND to Enable : 0v

- OUTA+ to OUTA- , using multimeter to bridge pins and no motor: 24v

- OUTB+ to OUTB- , using multimeter to bridge pins and no motor: 24v

Other things which may or may not be useful:

- Send jog commands from CNCJS, no movement

- Send GRBL commands from PUTTY, no movement

- Circuit continuity (looks like a diode symbol on the multimeter? I think?) verified for both A and B on motor

How else can I track down the problem?

After weeks of trying to solve this or even just understand if this is broken, any help would be incredibly appreciated!!!

Dan