Currently, the control is performed using the “100: 1 Micro Metal Gearmotor HP 6V with Extended Motor Shaft”.

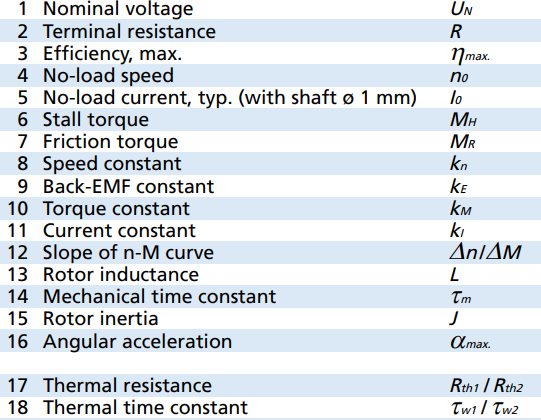

I want to know the information related to the motor.

The picture is the information I want.

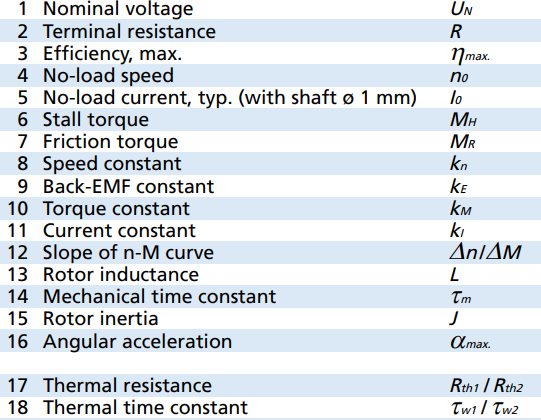

Currently, the control is performed using the “100: 1 Micro Metal Gearmotor HP 6V with Extended Motor Shaft”.

I want to know the information related to the motor.

The picture is the information I want.

Hello.

You can find information about many of these parameters, on the product page and in the datasheet for our Micro Metal Gearmotors (which you can find under the resources tab). The datasheet also includes performance curves for the motors. In the datasheet specs and performance curves you can find the rated/nominal voltage, maximum efficiency, no-load speed, no-load current, and stall torque. In the rest of this post, I will tell you how you can derive or estimate the values that are not explicitly listed and which parameters we have not characterized.

Before getting too far though, I want to point out that all the literature I have seen denotes torque constant with Kt, not Km, which is generally used for the motor constant, so that is the convention I will follow.

The armature/terminal resistance (R) is the rated voltage divided by the stall current.

The back emf constant (Ke) can be approximated by the rated voltage divided by the free run-speed at the rated voltage. I expect the speed constant (Kn) to be the inverse of that.

The motor torque constant (Kt) is the inverse of the slope of the current-versus-torque line which you can find from the performance curve for your motor in the datasheet. The motor constant (Km) is the torque constant divided by the square root of the armature resistance.

You can approximate the moment of inertia (J) of the rotor using the dimensions of the output shaft. The output shaft is made of stainless steel, and its dimensions can be found in the motor’s dimension diagram. That diagram is included in the datasheet, and you can also find it separately on the product page under the resources tab.

I am not exactly sure what you mean by friction torque. If you mean the torque needed to overcome the motor’s static friction, we have not characterized that. If you mean the torque friction exerts on the motor during operation, that is the product of the motor’s speed (in rad/s) and the viscous friction constant (b). The viscous friction constant can be determined by dividing the no-load current by the no-load speed and multiplying by the motor torque constant.

The theoretical mechanical time constant can be calculated using the following formula where “J” is the rotor’s moment of inertia, “b” is the coefficient of viscous friction, and “Ke” is the motor’s back-emf constant:

time constant = J×R/(R×b+Ke×Kt)

The inductance (L) of our 6V High-Power (HP) Micro Metal Gearmotors is about 0.6mH.

I am not familiar with a current constant parameter for DC motors, can you tell me what that is?

We have not characterized the n-M curve, the maximum angular acceleration, the thermal resistance, or the thermal time constant of our motors, and we do not have any suggestions for how you could determine those.

- Patrick