I am trying to design a Raspberry Pi / Arduino arm with reasonably precise control with arms made of lightweight acrylic rod. Rather than using stepper motors, I was thinking of using high power metal gearmotors instead. I want to count quadrature encoder ticks instead of relaying on the stepper motor steps.

Specifically:

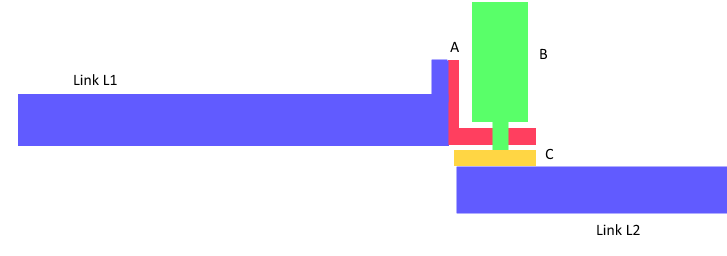

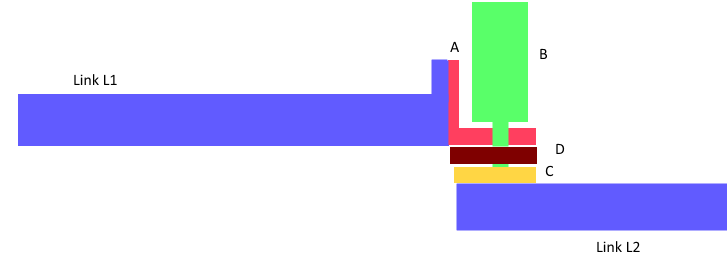

Bolting a Gearmotor Bracket (A) to one acrylic link.

Attaching the gearmotor (B) to the bracket (A)

Attaching the shaft of the gearmotor (B) to a mounting hub (C)

Bolting the mounting hub (C) to a second acrylic joint.

Using:

A) Pololu 25D mm Metal Gearmotor Bracket Pair

B) 172:1 Metal Gearmotor 25Dx71L mm HP 6V with 48 CPR Encoder

C) Pololu Universal Aluminum Mounting Hub for 4mm Shaft, #4-40 Holes (2-Pack)

L1) and L2) Acrylic arm link assembly

I have two questions:

Is this kind of motor appropriate to use? If I put torque load on the motor and provide power to keep it in a fixed position, will it suffer damage being “stalled” like that for extended periods of time (assuming I keep the power below the specified limits).

Do I need to worry about bending stresses on the motor shaft? I was thinking of placing a thrust bearing (D) between the gearmotor and the mounting hub to handle some of the stresses (see below). Is that necessary?

Thanks!