Hello Pololu forums. Looking for a little bit of support and feedback for a STSPIN220 Stepper Motor Driver.

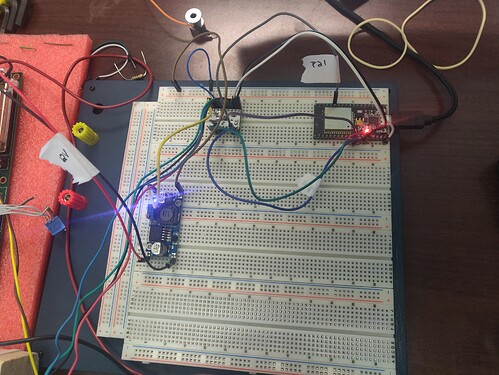

My motor: Trinamic QSH2818-32-07-006

Driver: STSPIN220

Controller: esp32 running micropython

Motor Power Supply: 12V stepped down to 3.8V with a buck converter module.

Vref: .134V (spec sheet on my motor says rated Phase Current is.67A, so far I have only had about .45A in a given coil at once according to my current clamp)

I am currently trying to get a stepper motor driver to microstep correctly, but I am finding it very inconsistent and am wondering if there are any tips or tricks, I can use to help me in the process. My application tries to get to a very specific step, and then hold that step for long periods of time. Speed is pretty much a non-issue.

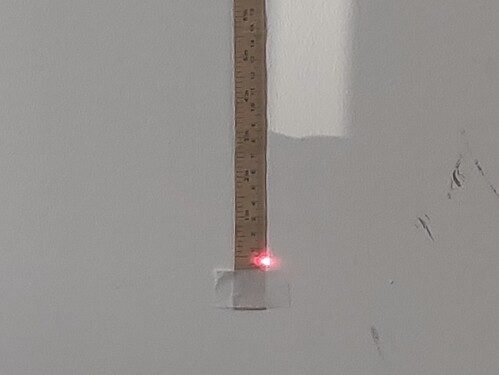

To test the motors and driver I am using a laser pointer attached to the shaft in a 3d printed block. Using Micro Python REPL, I just send the stepper motor driver individual step commands in either direction, then notate how far the motor is shifting from the previous position.

I am hoping to get down to 1/64th microsteps per step, but as I have incrementally tested the apparatus, I am noticing some strange behavior I am trying to understand. While I am in 1/8 stepping mode, the microsteps can vary in distance quite a bit. They always add up to the proper amount and seem to follow a pattern, but sometimes I get a lot of movement, and sometimes just a little.

| Eigth Step Mode | |||

|---|---|---|---|

| start | 0 | pretty much exactly 0, bouncy and noisy. | |

| 1r | 0.6 | ||

| 1r | 1.5 | ||

| 1r | 2.8 | ||

| 1r | 4.2 | ||

| 1r | 5.1 | ||

| 1r | 5.8 | bouncy, noisy | |

| 1r | 5.9 | ||

| 1r | 6.1 | bouncy, noisy | |

| 8f | 0 | bouncy, noisy | |

| start 0 | Moved the point down a bit under 1, this stopped the bouncy and noisy at this threshold |

The left column shows the command I gave the stepper motor, with the digit being the number of steps, and r or f indicates the direction. The right column shows the distance from 0 on the tape measure. The bouncy and noisy notation seems to be when it reaches some sort of resonance point? I did not notice it on ¼ or ½ step modes.

So sometimes I get a much as 1.3mm in a microstep, and sometimes as little as .1.

Am I putting in too much current, too little, or are these just the limitations of this motor driver?

Thanks for the help.