I am new at computer controlled side of servos and am working on a project using servos to act as analog gauge needles. I found that the Futaba 3004 that I purchased has a range of about 200 degrees, which sounds about where most better servos perform.

My question is about the internal stop(s) on the servo. Are there CW and CCW stops, or is it one stop that acts as both stops? I know that you can mod to get continuous rotation, but does that remove your reference point for calibrating the servo for neutral?

I want to keep the cost of this project down (there could be 6-8 gauges, since I’m running a 727 8-servo serial controller) and I find the cost of sail winches prohibitive, and is there a difference between a moded servo and a sail winch?

Thanks for your input!

DaveP in Ohio

Sorry to be the bearer of bad news. Usually hobby servos only have one mechanical stop, a peg sticking up from one of the gears that hits another gear when it rotates too far. The problem is that tab is there for a good reason.

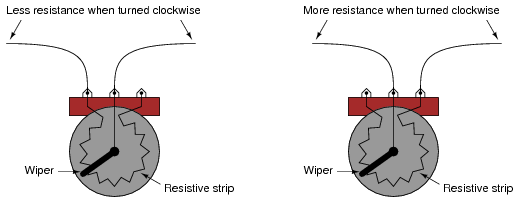

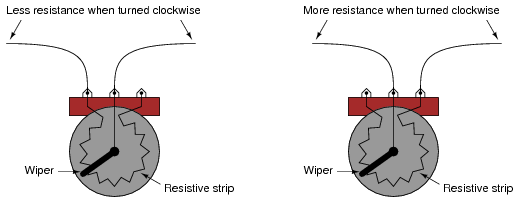

A servo measures it’s position using a rotary potentiometer, the same kind you would expect to find behind most volume control knobs. Potentiometers consist of a resistive strip, with a “wiper” that rotates with the output shaft, dragging along the strip. As the wiper moves, the resistance between the wiper and either end of the strip changes. If the potentiometer is wired up as a voltage divider, the resulting change in voltage can be measured to determine the position of the wiper, and the servo output shaft it’s connected to.

Most potentiometers have a flat semicircle of resistive material, so the wiper can only make part of a full turn (lets say 270 degrees for a guess) until it’s off of the strip entirely. Potentiometers generally have built-in stops at the ends their range, but if commanded to a servo motor could easily break through these stops, damaging the potentiometer in the process. The mechanical stop in the servo gear train is there to protect the potentiometer.

When you modify a servo for continuous rotation, you cut off the gear stop, but you also disconnect the potentiometer from the output shaft of the servo, or cut it out entirely and replace it with fixed resistors. A modified servo is essentially a gearmotor with a built-in speed controller in a compact package, so it’s great for things like wheels, but you no longer have position control.

Sail winch servos use multi-turn potentiometers, which have a helical resistive strip, so they can make multiple complete revolutions. These are more complicated to manufacture, and thus more expensive, but it is convenient when you really need 360+ degree rotation.

So, do you really need your needles to move more than ~200 degrees? Also, will you be unhappy with the noise that 8 servos are going to make twitching all the time?

-Adam

I thought that I had already known the answers…  I can live with 200 degrees, but more sweep would have been nice for cosmetic reasons.

I can live with 200 degrees, but more sweep would have been nice for cosmetic reasons.

Servo twitch noise? When I fire up the engine on the racing simulator with the 750 watt subwoofer turned up I doubt that I will even notice them!

There’s just something cool about seeing needles swinging around when you rev up those Ferraris and Porsches. Oh, and the Hondas and Beetles too…

Sounds very cool! I would love to see pictures/videos of it when its done.

-Adam

this might be a reasonable choice for the task: pololu.com/catalog/product/522

I can live with 200 degrees, but more sweep would have been nice for cosmetic reasons.

I can live with 200 degrees, but more sweep would have been nice for cosmetic reasons.