Hi,

I have a mini maestro controlling 3 servos. 2 using a slide pot and one on a switch.

They all work great until I move the slide pot slowly and then the jittering occurs!

I initially ran the system off 4x standard AA batteries through the maestro.

I then upgraded to higher capacity 3000 m/ah rechargeable batteries, which was slighly worse and have now plugged them into a 5v power supply offering 5A

I believe its still a current thing but dont know where to go next?

I checked the Maestro control centre and you can see the servos moving in the target area on the Status Tab.

Any help would be appreciated.

Thanks

I would expect a 5V, 5A supply to be fine for powering 3 standard servos and the Maestro. Please note that 5V is right at the minimum operating voltage of the Maestro, but if you connected it to the Maestro Control Center through USB and the jitter persists, then it is likely not the cause of the problem.

If you are using a potentiometer to control the servos, it’s possible that noise from that could be causing jitter. Could you try monitoring your slide potentiometer input(s) in the “Status” tab of the Maestro Control Center and see if they look noisy (particularly when you move it)? You might also try moving the servos to different channels and controlling them directly through the slider in the Maestro Control Center to see if the problem still happens when it isn’t being controlled by the potentiometer.

Brandon

Hi Brandon,

Thanks for getting back with me. I have now used a couple of mini maestros with the same effect, but ONLY when the slide pot is connected. Otherwise there is no movement or jitter. So it looks like the slide pot is the problem. In the control centre the jitter is obvious. I’m using a Bourne 10k slide pot. Is there anything I can do to stop the noise or maybe a different pot?

Thanks, Jon

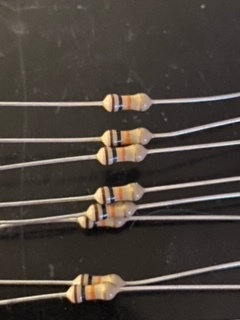

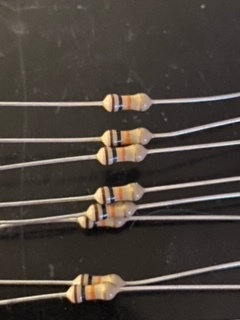

You might try adding a low-pass filter to the potentiometer input signal. This Instructable tutorial looks like a good reference for doing that.

You could also try taking an average of several readings in your script to try to smooth it out in software. For example, you could use this snippet of code for averaging 20 readings from channel 1:

1 get_position #take initial reading

19 begin dup while swap #loop 19 times, adding additional reading to the total each loop

1 get_position plus #take reading and add it to total

swap 1 minus #subtract from loop counter

repeat

drop

20 divide #divide total by number of readings

It might be even smoother to modify your code to use a running average, but that would be more complicated.

If you do try adding some averaging to your script and run into problems, you could post what you have tried so far here and I would be happy to help.

Brandon

Thanks again for your help Brandon.

I’ve gone back to the basics again and re wired a mini maestro to see if the problem was the board.

With the new maestro the same problem occurs but without the slide pot connected.

If I attach a button on channel 0 and a servo on Channel 5, the button channel is vibrating, the target showing 254-255.75

Is this because the script is constantly trying to get_position ?

A real idiot here, sorry!

begin

0 get_position #get the value of the input on channel 0

500 less_than if #if it is less than 500

4000 5 servo #move the servo on channel 5 to 1000us

else #otherwise,

8000 5 servo #move the servo on channel 5 to 2000us

endif

1 get_position # get the value of the pot, 0-1023

4 times 4000 plus #scale it to 4000-8092, approximately 1-2 ms

dup #duplicate the scaled value

3 servo #set servo 3 to the scaled value

4 servo #set servo 4 to the scaled value

repeat

It is fine to constantly call get_position. It looks like that script is set up to use 1 button and 1 potentiometer; can you clarify what you had connected to each channel and what behavior you were seeing? Also, could you post pictures of your setup that show all of your connections?

Brandon

Hi Brandon,

On channel 0 - I have one button to control 1 servo ( Blink)

On channel 1 - I have the slide pot to control 2 servos (2 eyes)

When the slide pot is at one end everything works as it should, however, if it is moved halfway, ( The eyes looking to one side, all the servos act irratically.

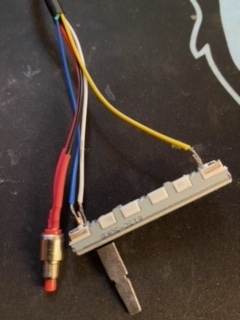

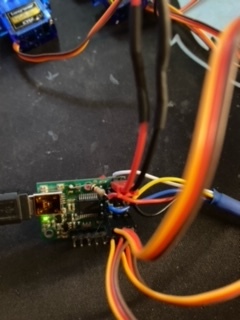

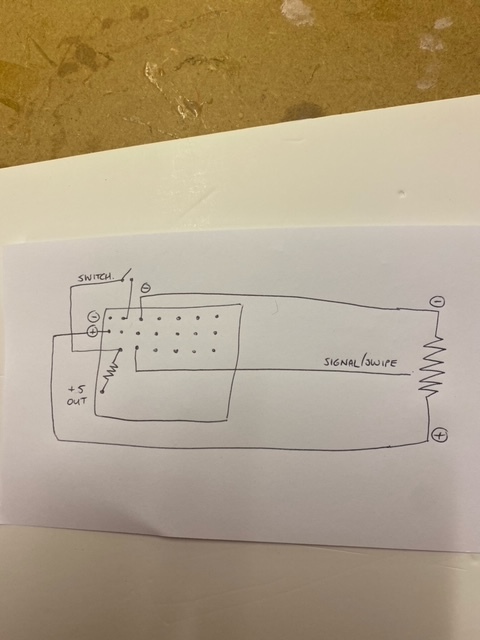

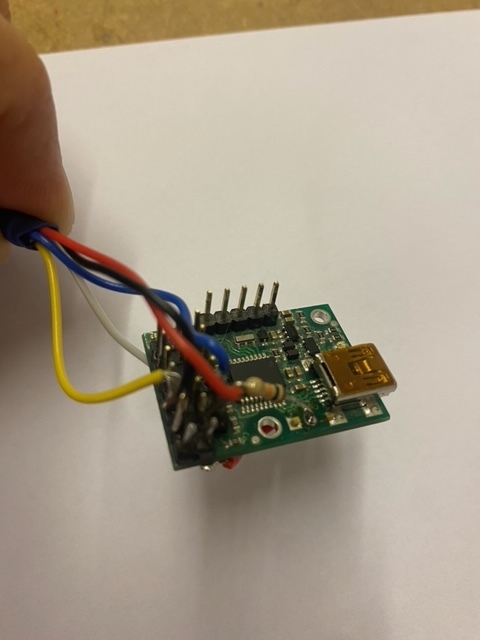

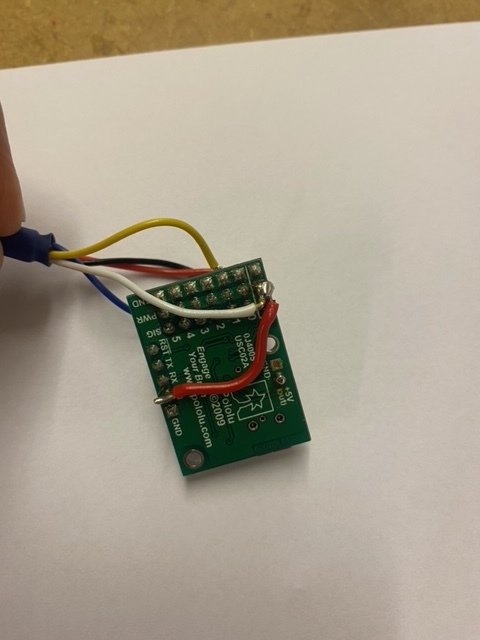

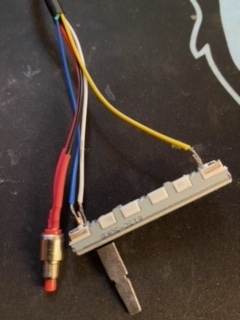

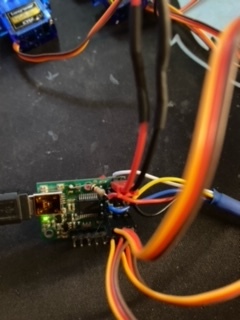

I’ve attached some images of the setup.

onedrive of videos

Any help would be great thanks,

Jon

Just to clarify, are you pressing the button in both of those videos? If so, the button behavior does not seem concerning to me. However, the potentiometer readings do look really unstable. It looks like it could be from something like an intermittent connection, so double checking your connections would probably be the first (and easiest) thing to do. You might also double check that your potentiometer is wired correctly (i.e. the ends are connected to 5V and GND, and the wiper is connected to the Maestro’s input channel pin).

It is hard to make out all of your connections in your picture, but it looks like you might be powering the potentiometer from the servo power rail (i.e. the same supply as your servos). If that’s the case, you might try powering it from the regulated 5V (out) pin on the Maestro to see if that makes any difference.

If you still have the same problem after that, could you post close-up pictures that clearly show all of your connections? A wiring diagram might help too.

Brandon

Are you still using your 5V, 5A power supply? If not, what are you using? The signal pins on the Maestro should only be used with 0-5V signals, so if you supply the Maestro power rail with 6V, you should use the 5V (out) pin on the Maestro to power your pot.

For now, could you try disconnecting all of the servos and running the system with just the button and pot connected to see how it behaves? If the pot is connected correctly and the channel is configured correctly, you should be able to see the channel value move smoothly from one end to the other as you move the pot. If it still seems erratic or doesn’t respond according to the pot, then that could suggest something is wrong with your wiring, the pot itself, or elsewhere in the setup.

Brandon

Unbelievably I solved the great mystery! I upgraded the firmware from 1.02 to 1.04 and it seems to have resolved the issue!

I did also re-solder the pot onto the 5v out like you suggested.

So thanks again for all your help

Jon

1 Like

My only problem that I have now, though it is still working., is that the red LED flashes 3x when using the servos.

I’m now using standard 1.5v AA batteries and asume that this is current draw.

As soon as I plug the maestro into the usb connected to my PC then the red lights disappear.

Will this cause a problem? do you recommend 2 power supplies?

Thanks,

Jon

From your description, I agree that it sounds like a power supply issue, and using a separate power supply for the logic side of the Maestro should solve that problem.

It sounds like you are using Alkaline AA batteries, which have a higher voltage per cell than NiMH, but NiMH batteries have a much steadier output when under load. You can find some more information in this Intronix article. So, if it is more convenient to power it from a single power source, you might get better results using a 5-cell pack of rechargable NiMH batteries.

Brandon