iiiii

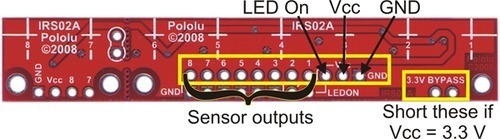

now works, when you put something black on the sensors they give the value 4000, do not know how such a mistake, it was the short circuit: /

as a code for to use with sensors, I visualized this link here:

pololu.com/docs/0J19/3

just do not understand how the error can always varies between -1000 and 1000, as the motor speed will vary so?,

can you explain me? and if possible exemplify me a code to use with this array of sensors? (to make the follower of lines).

What I want is for the engines to turn the two maxima velocidadequando sensors are about half the black line (00011000, thus exemplifying the best), and that when this state is established: 00110000 engine right little slow, but when check this: 11000000, the right engine very slow, you know? …

I worked out the following schedule:

/*Bibliotecas necessárias*/

#include <Servo.h>

/*variáveis de configuração*/

int nsensores = 8;

int rmotor = 9;//pino do motor direito (PWM);

int lmotor = 10;//pino do motor esquerdo (PWM);

int sensor[] = {8,7,6,5,4,3,2,1};

/* variaveis auxiliares*/

int senval[]= {0,0,0,0,0,0,0,0};//variavel onde será guardado os valores dos sensores.

int Rtarguetval = 0;// valor pretendido para o motor direito.

int Ltarguetval = 0;// valor pretendido para o motor esquerdo.

int nowvalR = 0; //valor actual do motor direito.

int nowvalL = 0;//valor actual do motor esquerdo.

int vel_max = 130;//velocidade máxima dos motores.

int CStop = 0;//

boolean stop = false;

double LineErrorVal = 0.0;

void setup(){

Serial.begin(9600);

pinMode (rmotor, OUTPUT);

pinMode (lmotor, OUTPUT);

DDRD = LOW;// portas 7..0 como inputs, aqui ligarei os 8 sensores.

}

void loop(){

stop = false;

//Lemos os valores dos sensores

readALLSensores();

if(senval[11111111]){

stop = true;

}

//vemos se estes valores se mantêm, duante 30ms

if(stop){

CStop++;

if (CStop >=30){

Rtarguetval = 0;

Ltarguetval = 0;

}

else{

stop = false;

}

}

//De seguida iremos determinar as velocidades para os motores, consoante o erro.

if(LineErrorVal < 0.0){

Ltarguetval = (int)(vel_max*(1-fabs(LineErrorVal)));

Rtarguetval = vel_max;

}else if (LineErrorVal > 0.0){

Ltarguetval = vel_max;

Rtarguetval = (int)(vel_max*(1-LineErrorVal));

}else{

Ltarguetval = (int)(vel_max);

Rtarguetval = (int)(vel_max);

}

//controlar os arranques e travagens dos motors.

if(Rtarguetval > nowvalR){

nowvalL +=1;

}else if (Rtarguetval < nowvalR){

nowvalL -=1;

}

if (Ltarguetval > nowvalL){

nowvalL +=1;

}else if(Ltarguetval < nowvalL){

nowvalL -=1;

}

// ter a certeza que a velocidade dos motores nao ultrapassam o valor desejado

if (nowvalL > vel_max){

nowvalL = vel_max;

}

if (nowvalR > vel_max){

nowvalR = vel_max;

delay(20);

}

}

//FUNÇÔES//

void readALLSensores(){

for(int i = 0; i < 8; i++)

{

senval[i] = digitalRead (sensor[i]);

}

}

int bestSensor(int sensor[]){

int bestSensor = 0;

for (int i=0; i < 8; i++)

{

if (sensor[i] == 1){

digitalRead (sensor[i]+1);

if (sensor[i] +1 == 0){

bestSensor = i;

}

}

else if(sensor[i] == 0){

digitalRead (sensor[i]+1);

if(sensor[i] +1 ==1){

bestSensor = i;

}

}

}

}

//retorna valores entre -1.0 e 1.0, consoante o erro da linha

// se a linha estiver ao centro, o erro é 0.0.

double lineError (int sensor[])

{

int best = bestSensor (sensor);

double error = 0.0;

// começando!!

if (best == 3 || best ==4){

error = 0.0;

}

else{ if(best == 2){

error = -0.3;

}

else{if (best = 1){

error = -0.6;

}

else{if (best = 0){

error = -1.0;

}

else{if (best = 5){

error =0.3;

}

else{if (best = 6){

error = 0.6;

}

else{if (best = 7){

error = 1.0;

}

{

return error;

}

}

}

}

}

}

}

}

but is for use with an array of 5 sensors “normal” with these sensors do not know and do heide, when you look at my schedule, my error ranges (-1 to 1) and this error as the engine speed will vary (try to look and realize I do not know how to explain), to use these sensors, percegi the error or is it 1000 or -1000, never varies in these numbers, hence my question …

could you me illustrate a simple code to “adapt” this array of sensors to the follower of lines?

thanks.