Hello Guys,

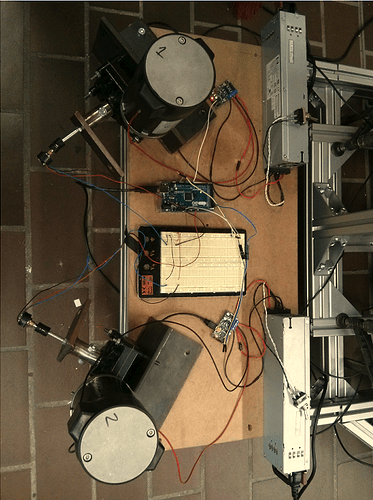

I am doing a Project on 2DOF Motion seat Simulator and in my code I want to use the pwm values and control the Speed of the Motor.

I have a pololu 18v25 simple Motor Controller, but as you know you can only Change the pwm frequency manually in the pololu application. So I wanted to know is there any protocol or any other way to Change These pwm values through arduino and Input it to pololu Motor Controller.

I will send you the code wriiten for Motomonster, I want write this for Pololu 18v25, please help me out, it is very important for me to do this.

/*

Arduino code for dynamic playseat 2DOF

*/

#include <SoftwareSerial.h>

#define BRAKEVCC 0

#define RV 2 //beware it's depending on your hardware wiring

#define FW 1 //beware it's depending on your hardware wiring

#define STOP 0

#define BRAKEGND 3

////////////////////////////////////////////////////////////////////////////////

#define pwmMax 255 // or less, if you want to lower the maximum motor's speed

// defining the range of potentiometer's rotation

const int potMini=208;

const int potMaxi=815;

////////////////////////////////////////////////////////////////////////////////

#define motLeft 0

#define motRight 1

#define potL A0

#define potR A1

////////////////////////////////////////////////////////////////////////////////

// DECLARATIONS

////////////////////////////////////////////////////////////////////////////////

/* VNH2SP30 pin definitions*/

/*int inApin[2] = {

7, 4}; // INA: Clockwise input

int inBpin[2] = {

8, 9}; // INB: Counter-clockwise input

int pwmpin[2] = {

5, 6}; // PWM input

int cspin[2] = {

2, 3}; // CS: Current sense ANALOG input

int enpin[2] = {

0, 1}; // EN: Status of switches output (Analog pin)

int statpin = 13; //not explained by Sparkfun

/* init position value*/

int DataValueL=512; //middle position 0-1024

int DataValueR=512; //middle position 0-1024

#define rxPin1 3 // pin 3 connects to smcSerial TX (not used in this example)

#define txPin1 4 // pin 4 connects to smcSerial RX

SoftwareSerial smcSerial1(rxPin1, txPin1);

#define rxPin2 7 // pin 3 connects to smcSerial TX (not used in this example)

#define txPin2 8 // pin 4 connects to smcSerial RX

SoftwareSerial smcSerial2(rxPin2, txPin2);

////////////////////////////////////////////////////////////////////////////////

// INITIALIZATION

////////////////////////////////////////////////////////////////////////////////

void setup()

{

// serial initialization

Serial.begin(115200);

}

// required to allow motors to move

// must be called when controller restarts and after any error// initialization of Arduino's pins

/* pinMode(statpin, OUTPUT); //not explained by Sparkfun

digitalWrite(statpin, LOW);

for (int i=0; i<2; i++)

{

pinMode(inApin[i], OUTPUT);

pinMode(inBpin[i], OUTPUT);

pinMode(pwmpin[i], OUTPUT);

}

// Initialize braked for motor

for (int i=0; i<2; i++)

{

digitalWrite(inApin[i], LOW);

digitalWrite(inBpin[i], LOW);

}*/

////////////////////////////////////////////////////////////////////////////////

///////////////////////////////// Main Loop ////////////////////////////////////

////////////////////////////////////////////////////////////////////////////////

void loop()

{

int sensorL,sensorR;

readSerialData(); // DataValueR & L contain the last order received (if there is no newer received, the last is kept)

// the previous order will still be used by the PID regulation MotorMotion Function

sensorR = analogRead(potR); // range 0-1024

sensorL = analogRead(potL); // range 0-1024

motorMotion(motRight,sensorR,DataValueR);

motorMotion(motLeft,sensorL,DataValueL);

}

////////////////////////////////////////////////////////////////////////////////

// Procedure: wait for complete trame

////////////////////////////////////////////////////////////////////////////////

void readSerialData()

{

byte Data[3]={

'0','0','0' };

// keep this function short, because the loop has to be short to keep the control over the motors

if (Serial.available()>2){

//parse the buffer : test if the byte is the first of the order "R"

Data[0]=Serial.read();

if (Data[0]=='L'){

Data[1]=Serial.read();

Data[2]=Serial.read();

// call the function that converts the hexa in decimal and that maps the range

DataValueR=NormalizeData(Data);

}

if (Data[0]=='R'){

Data[1]=Serial.read();

Data[2]=Serial.read();

// call the function that converts the hexa in decimal and maps the range

DataValueL=NormalizeData(Data);

}

}

if (Serial.available()>16) Serial.flush();

}

////////////////////////////////////////////////////////

void motorMotion(int numMot,int actualPos,int targetPos)

////////////////////////////////////////////////////////

{

int Tol=20; // no order to move will be sent to the motor if the target is close to the actual position

// this prevents short jittering moves

//could be a parameter read from a pot on an analogic pin

// the highest value, the calmest the simulator would be (less moves)

int gap;

int pwm;

int brakingDistance=30;

// security concern : targetPos has to be within the mechanically authorized range

targetPos=constrain(targetPos,potMini+brakingDistance,potMaxi-brakingDistance);

gap=abs(targetPos-actualPos);

if (gap<= Tol) {

motorOff(numMot); //too near to move

}

else {

// PID : calculates speed according to distance

pwm=195;

if (gap>50) pwm=215;

if (gap>75) pwm=235;

if (gap>100) pwm=255;

pwm=map(pwm, 0, 255, 0, pwmMax); //adjust the value according to pwmMax for mechanical debugging purpose !

// if motor is outside from the range, send motor back to the limit !

// go forward (up)

if ((actualPos<potMini) || (actualPos<targetPos)) motorGo(numMot, FW, pwm);

// go reverse (down)

if ((actualPos>potMaxi) || (actualPos>targetPos)) motorGo(numMot, RV, pwm);

}

}

////////////////////////////////////////////////////////////////////////////////

void motorOff(int motor){ //Brake Ground : free wheel actually

////////////////////////////////////////////////////////////////////////////////

/*digitalWrite(inApin[motor], LOW);

digitalWrite(inBpin[motor], LOW);*/

smcSerial1.write(0xE0);

smcSerial2.write(0xE0);

analogWrite(pwmpin[motor], 0);

}

////////////////////////////////////////////////////////////////////////////////

/*void motorOffBraked(int motor){ // "brake VCC" : short-circuit inducing electromagnetic brake

////////////////////////////////////////////////////////////////////////////////

digitalWrite(inApin[motor], HIGH);

digitalWrite(inBpin[motor], HIGH);

analogWrite(pwmpin[motor], 0);

}*/

////////////////////////////////////////////////////////////////////////////////

void motorGo(uint8_t motor, uint8_t direct, uint8_t pwm)

////////////////////////////////////////////////////////////////////////////////

{

if (motor <= 1)

{

if (direct <=4)

{

// Set inA[motor]

if (direct <=1)

//digitalWrite(inApin[motor], HIGH);

smcSerial1.write(0x85);

else

//digitalWrite(inApin[motor], LOW);

smcSerial1.write(0xE0);

// Set inB[motor]

if ((direct==0)||(direct==2))

//digitalWrite(inBpin[motor], HIGH);

smcSerial2.write(0x85);

else

//digitalWrite(inBpin[motor], LOW);

smcSerial2.write(0xE0);

analogWrite(pwmpin[motor], pwm);

}

}

}

////////////////////////////////////////////////////////////////////////////////

void motorDrive(uint8_t motor, uint8_t direct, uint8_t pwm)

////////////////////////////////////////////////////////////////////////////////

{

// more readable function than Jim's (for educational purpose)

// but 50 octets heavier -> unused

if (motor <= 1 && direct <=4)

{

switch (direct) {

/*case 0: //electromagnetic brake : brake VCC

digitalWrite(inApin[motor], HIGH);

digitalWrite(inBpin[motor], HIGH);

break;*/

case 3: //Brake Ground (free wheel)

//digitalWrite(inApin[motor], LOW);

//digitalWrite(inBpin[motor], LOW);

smcSerial1.write(0xE0);

smcSerial2.write(0xE0);

break;

case 1: // forward : beware it's depending on your hardware wiring

//digitalWrite(inApin[motor], HIGH);

//digitalWrite(inBpin[motor], LOW);

smcSerial1.write(0x85);

smcSerial2.write(0xE0);

break;

case 2: // Reverse : beware it's depending on your hardware wiring

//digitalWrite(inApin[motor], LOW);

//digitalWrite(inBpin[motor], HIGH);

smcSerial1.write(0xE0);

smcSerial2.write(0x85);

break;

}

analogWrite(pwmpin[motor], pwm);

}

}

////////////////////////////////////////////////////////////////////////////////

// testPot

////////////////////////////////////////////////////////////////////////////////

void testPot(){

Serial.print(analogRead(potL));

Serial.print(";");

Serial.println(analogRead(potR));

delay(250);

}

////////////////////////////////////////////////////////////////////////////////

void testpulse(){

int pw=120;

while (true){

motorGo(motLeft, FW, pw);

delay(250);

motorOff(motLeft);

delay(250);

motorGo(motLeft, RV, pw);

delay(250);

motorOff(motLeft);

delay(500);

motorGo(motRight, FW, pw);

delay(250);

motorOff(motRight);

delay(250);

motorGo(motRight, RV, pw);

delay(250);

motorOff(motRight);

Serial.println("testpulse pwm:80");

delay(500);

}

}

////////////////////////////////////////////////////////////////////////////////

// Function: convert Hex to Dec

////////////////////////////////////////////////////////////////////////////////

int NormalizeData(byte x[3])

////////////////////////////////////////////////////////////////////////////////

{

int result;

if ((x[2]==13) || (x[2]=='R') || (x[2]=='L')) //only a LSB and Carrier Return or 'L' or 'R' in case of value below 16 (ie one CHAR and not 2)

{

x[2]=x[1]; //move MSB to LSB

x[1]='0'; //clear MSB

}

for (int i=1; i<3; i++)

{

if (x[i]>47 && x[i]<58 ){//for x0 to x9

x[i]=x[i]-48;

}

if (x[i]>64 && x[i]<71 ){//for xA to xF

x[i]=(x[i]-65)+10;

}

}

// map the range from Xsim (0 <-> 255) to the mechanically authorized range (potMini <-> potMaxi)

result=map((x[1]*16+x[2]),0,255,potMini,potMaxi);

return result;

}