Though I still have a lot to try and learn with my RPB-202 robot, I couldn’t resist starting a mini-sumo robot project, just 'cause it looks so fun! With inspiration from excellent blog posts on the 2015 LVBots mini-sumo competition detailing the design of some of the robots, I launched the CAD software and started designing mine. I evaluated the option of using laser-cut acrylic for the chassis but ended-up choosing 3D printing as the base for the design considering it offered more design flexibility and was simpler for me to build (no need to glue and/or bend). I will build two robots so I can have them compete against each other and also so that I can get my son to compete against me!

Specifications:

Overall dimensions: W: 96mm, L: 95mm, H: 39mm (3.78" x 3.71" x 1.54" approx)

Weight: 205 g

Motors*: 2 x 75:1 Micro Metal Gearmotor HPCB 6V or 2 x 50:1 Micro Metal Gearmotor HPCB 6V with Micro Metal Gearmotor Brackets (pair).

Wheels: 2 x Solarbotics RW2 Wheel (external set screw)

Battery: 2S Li-Po 800 mAh (55 mm x 31 mm x 17 mm max size)

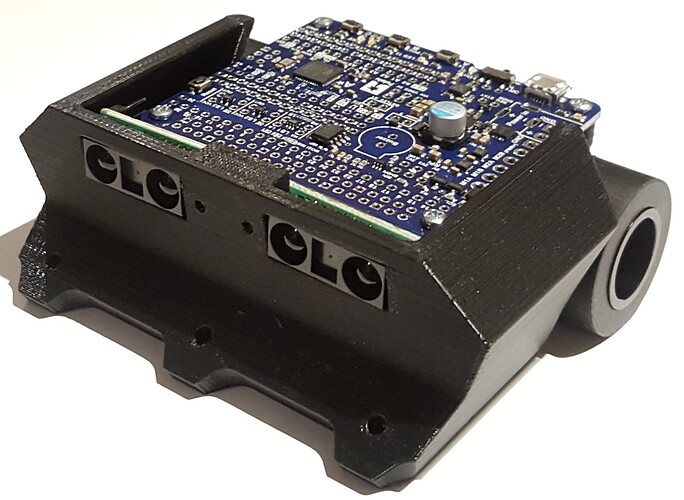

Microcontroller: A-Star 32U4 Robot Controller LV with Raspberry Pi Bridge (SMT Components Only)

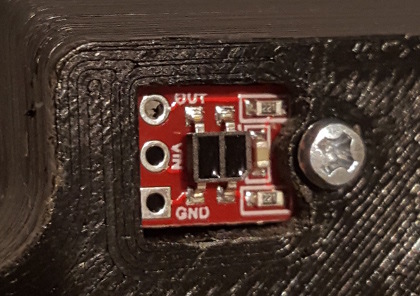

Sensors: 2 x Sharp GP2Y0A60SZLF Analog Distance Sensor, 2 x QTR-1RC Reflectance Sensors and 1 x MinIMU-9 v5 Inertial Measurement Unit.

*I bought two pairs of motors (50:1 and 75:1) and will build one robot with each set to compare which is better, speed or torque and allow use of different strategies.

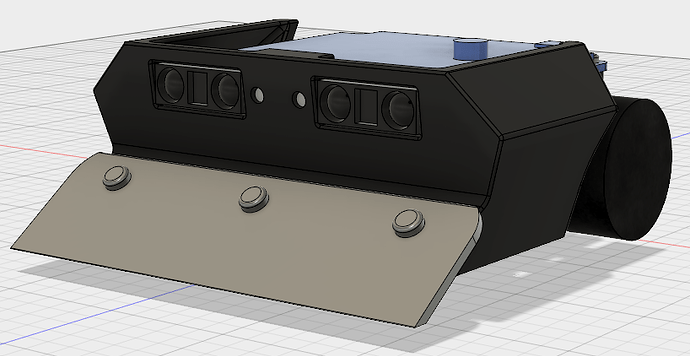

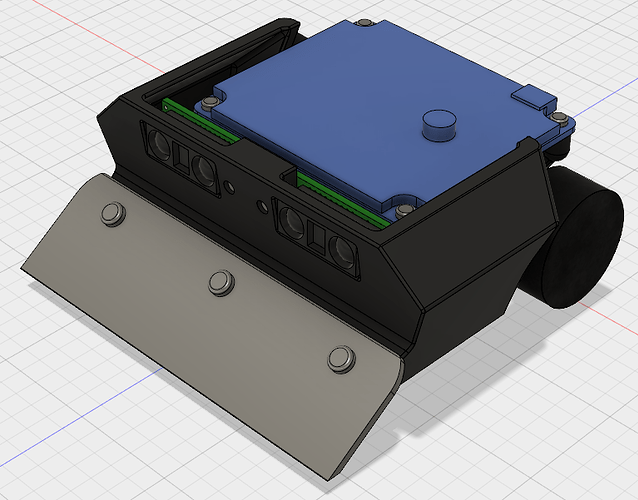

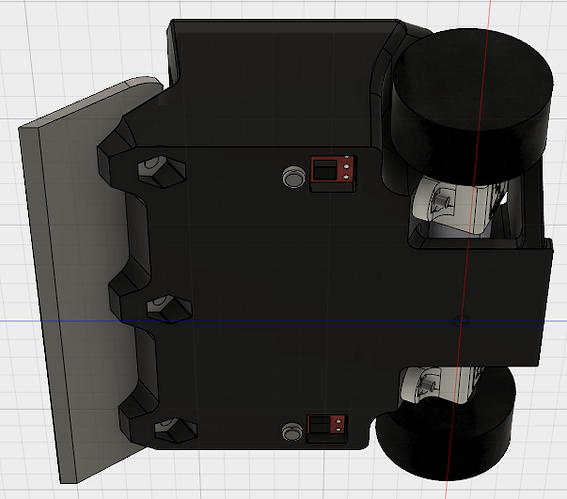

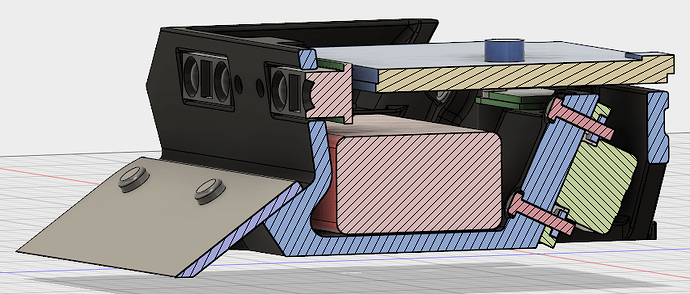

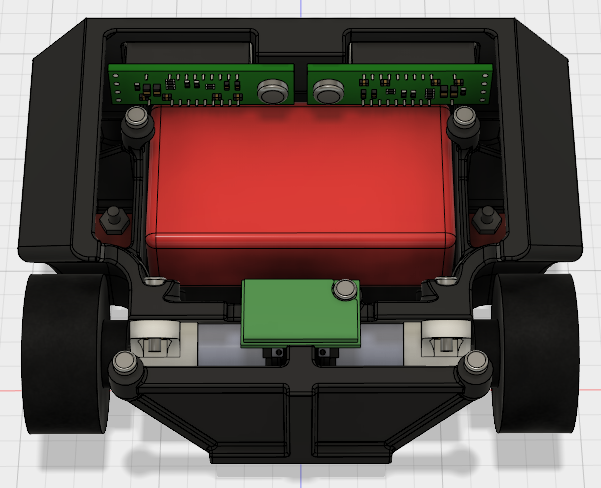

Below are a few snapshots of the assembly in the CAD software:

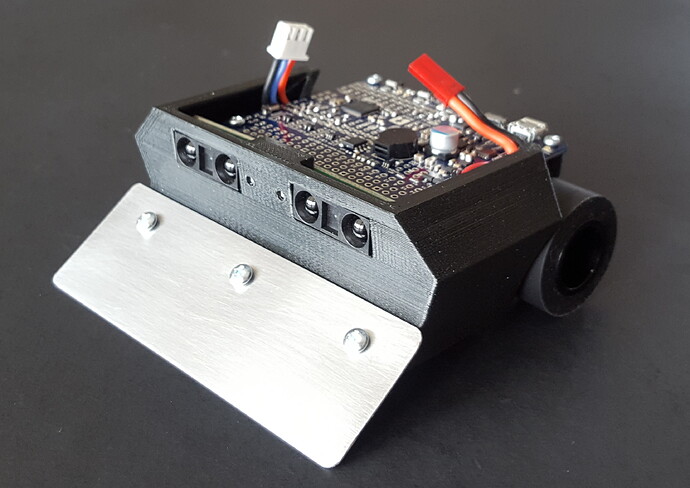

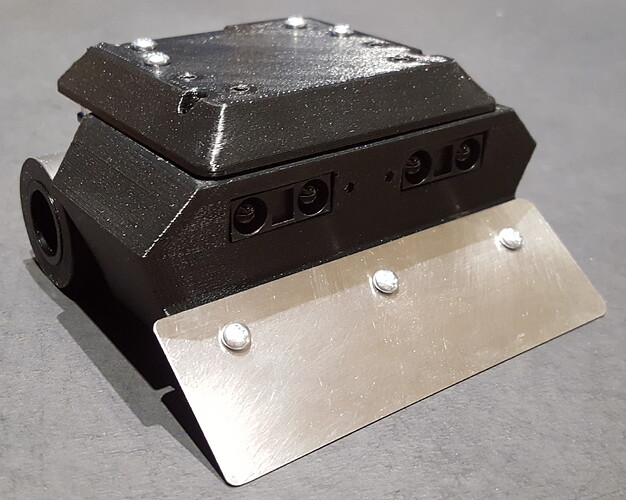

Forward view showing blade and Sharp GP2Y0A60SZLF Analog Distance Sensor

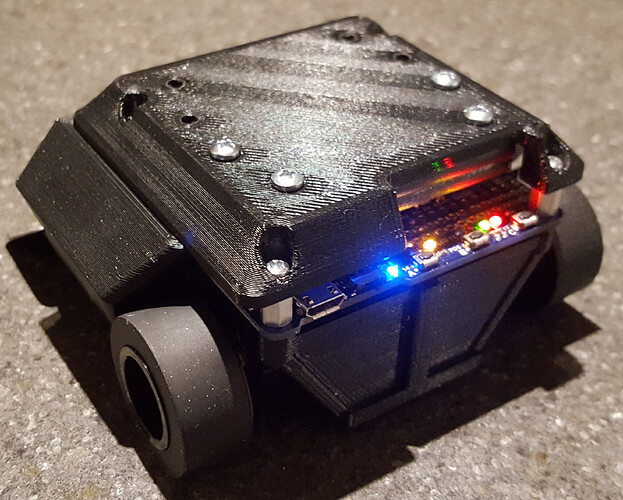

Top view showing A-Star 32U4 Robot Controller LV on top.

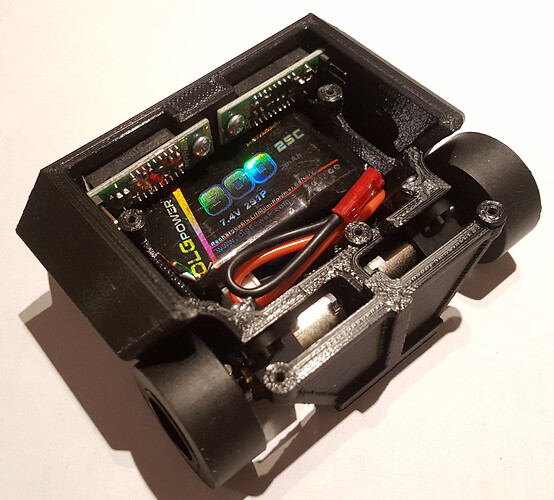

Top-rear view (with A-Star removed) showing the internals; 800 mAh 2S li-po battery and MinIMU-9 v5 IMU.

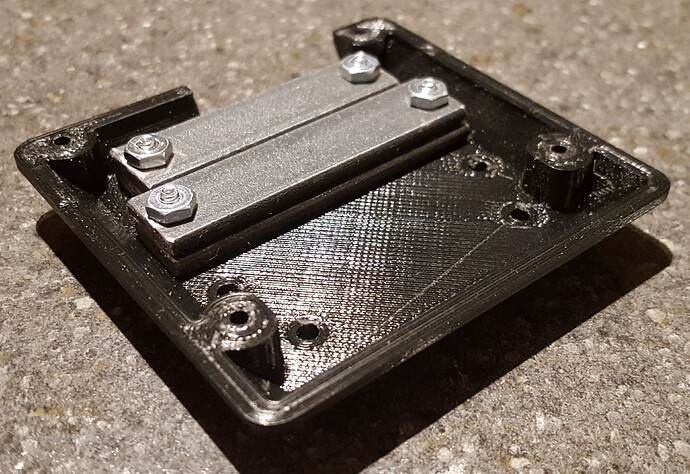

View from below showing the blade attachment nuts, QTR-1RC Reflectance Sensors and angled motor brackets.

Section cut showing the angled motor bracket and battery snug fit.

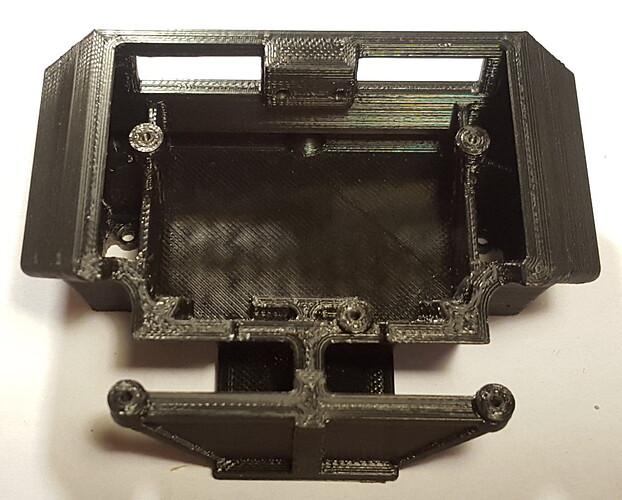

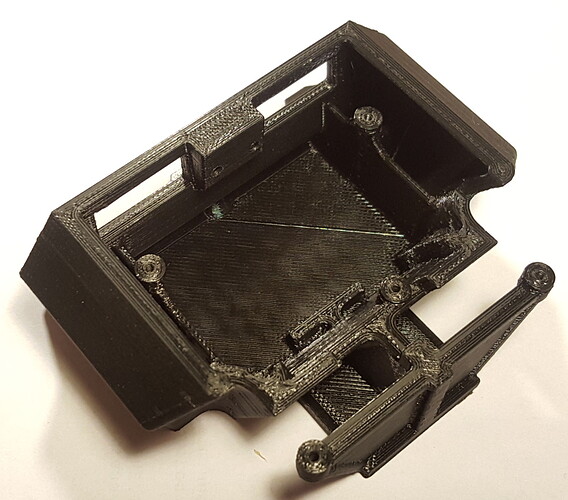

I selected the Sharp IR sensors as primary sensors to locate the opponent because I already had four available and because they seemed to work well on @kevin’s Roku mini-sumo. I selected the A-Star 32U4 Robot Controller LV for the simplicity of having one single board with everything I need and also because I have experience with it. I had the objective of having the A-Star controller on the top so I could use the buttons and leds as user interface. I positioned the motor brackets at an angle to saves axial space, allowing me to fit the battery at the bottom of the chassis, keeping the A-Star on top and the overall height low. The angle also allows direct line of sight to the bolt holes allowing the use of a drill to finish the diameter after 3D printing and screwdriver access to tighten the screws. I positionned the MinIMU-9 v5 Inertia Measurement Unit in the space available below the A-Star and as close as possible to the axis of the motors. Finally, I positionned one QTR-1RC Reflectance Sensors in front of each wheel for ring border detection. As this is my first mini-sumo robot, I wanted to keep sensors to a minimum and have simpler code.

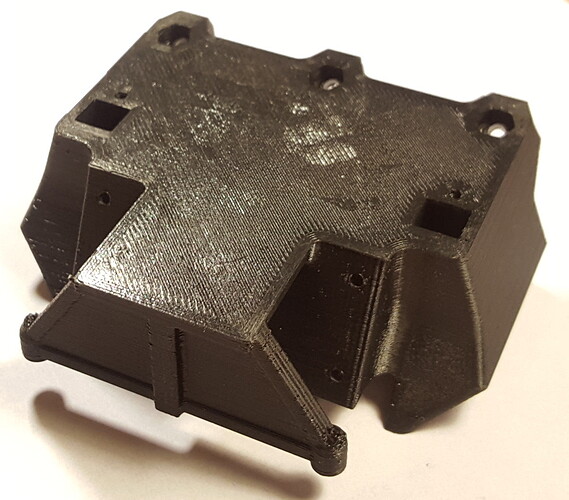

With all the components at their approximate position, I modeled the chassis around them providing mounting points for each component. I designed the external shape with angled surfaces as a “stealth” feature to divert the reflection of the opponent’s IR sensors either downward or upward. There is no “cover” but the edge of the chassis is higher than the components of the A-Star to protect it in case the robot rolls over. I may add one later using standoffs at the A-Star attachment points.

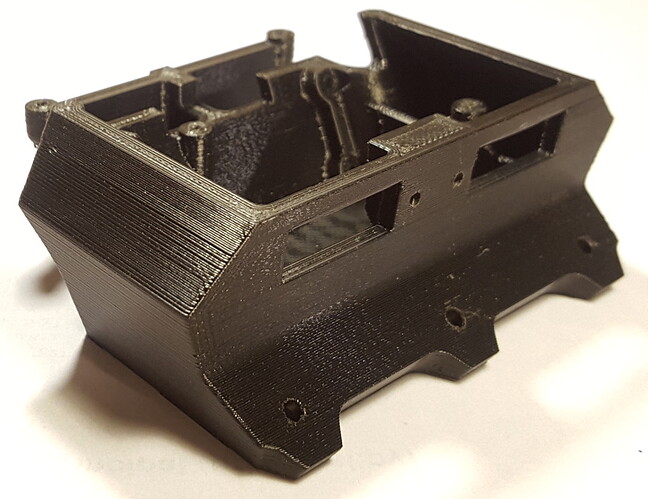

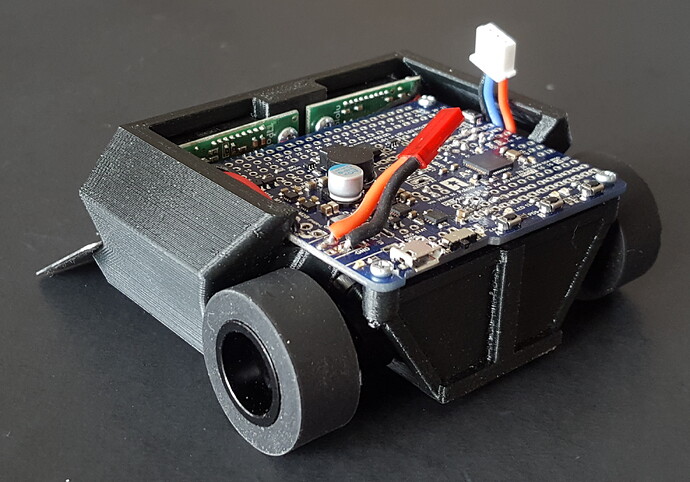

I got a first prototype chassis printed from a local source on 3D Hubs (pictures below). To my relief, all the components fit nicely inside the chassis except for a small ajustment I needed to make with a Dremel to clear small surface mount components near the bolt holes of the QTR sensors. Once I complete the assembly of the first prototype and am satisfied with it, I will update the 3D model and have the second chassis printed. I will also make the 3D model public at that time for anyone who would be interested in building one.

That’s it for now, I’ll post more as the build progresses.