of course thank you again

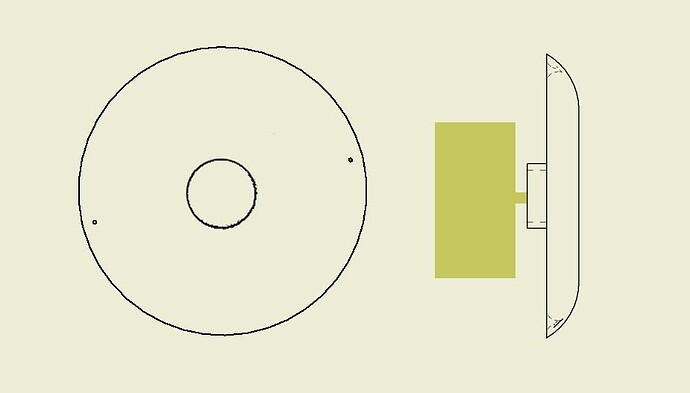

so specific tool for my soft testing, the entire mechanism is composed only of three parts capsule, motor and plastic disc, I added the image below

disk: ⌀ 44 mm

width 5 mm

dimension of motor is important because I must put it in capsule with limited dimensions, so size of motor must be:

Diameter: 25 or at least ⌀30 mm maximum

Width better 20 mm or at least 40 mm maximum

but but main thing, motor must give me exactly this possibilities, so here is sequence, but first, description what is what, to be clear:

[ul]A. Step … < step point of sequence

B. = +180° < addition of distance from step to step in other words turn on 180°

C. (get this step…) < movement to get actual point from zero and back to zero, except 0° which returns to itself.

D. On first and last steps is shown the same maximal diapason from actual point to most distant point and back to itself - 900° + 900° in total 1800°[/ul]

here is exactly what I want from motor in terms of time/speed and control possibilities:

[ul]

Step -1 = -180° (get this point from 0° -180° and back +180°) from step-1 to step4 + 900° and back - 900°total distance 1800°

Step 0 = 0° (from 0° to 0° in minus -180° and +180°, in plus + 720 and -720°)

Step 1 = +180° (get this step from 0° + 180° and back - 180°)

Step 2 = +180° ( get this step from 0° + 360° and back - 360°)

Step 3 = +180° ( get this step from 0° + 540° and back - 540°)

Step 4 = +180° ( get this step from 0° + 720° and back - 720°) from step4 to step-1 - 900° and back + 900°total distance 1800°[/ul]

so I need possibility of movement from 0 for example to the most distant (point4) what is (+ 720°- 720°) in this case time of this action as any other depends on time of action of this: if I go from last step in this sequence (step4) through the whole steps diapason this way: 4, 3, 2, 1, 0, -1, and back 0, 1, 2, 3, 4. whole this movement (- 900° and back + 900°total distance 1800°) must be equal 1 second or at least 1.5 sec

I’m not sure which motor can give me this speed when it makes movement in opposite direction and control possibilities of course, meets all of these requirements including size, so here I need your help please