In addition to my walking remote control airsoft robot, Onyx, I also pour love, time, and money into an autonomous rover, nicknamed “The Money Pit.” I’m currently up to version 5, called “V for Victory” because I’m great at modesty! ![]()

I placed 2 out of 20 at the autonomous race meet-up in Oakland today. Here’s a training run (I don’t have video from actually competing, because I was focused on other things then!)

In addition to driving on race tracks indoors, this chassis is intended to be robust. It can, for example, climb stairs!

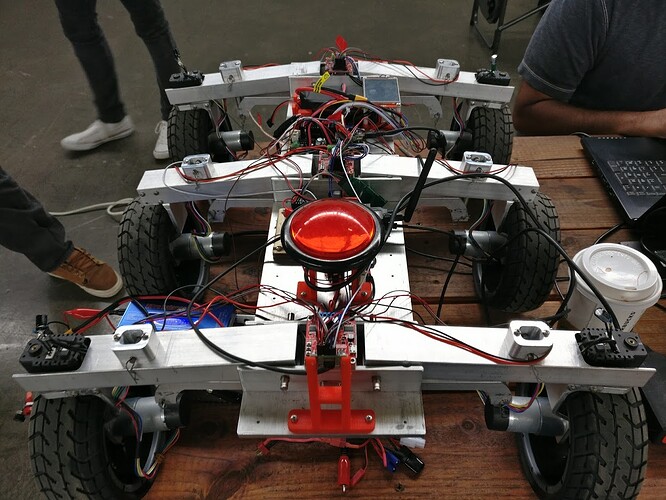

Here’s a glory shot of the 'bot:

The bot is using a variety of components from Pololu:

- 3x RoboClaw motor controllers (because all six wheels are driven, and have encoders)

- 6x Pololu 37D 50:1 gear motors with encoders (getting it all integrated into one – how great is that?!)

- 1x Pololu 5V/2.2A buck converter (to power the Raspberry Pi) (I like that they’re enough oomph to actually power a full Pi)

- Tons of pre-crimped “Du Pont” wires and housings (because life is too short to crimp my own!)

It also uses a number of other parts:

- Raspbery Pi 2B, with camera, for knowing where to go

- 1x Teensy 3.2 microcontroller to talk to everything

- 1x Big Red Button for emergency power off

- 1x FlySky FS-GT2E 3-channel RC controller as emergency brake

- 4x Dynamixel AX-12A servos for steering

- SPI TFT display with resistive touchscreen

- Home-made power switch, distribution, and interface board

- 5 Ah 3S LiPo from a cheap Chinese place, because I don’t fear fire!

- 7" slick (and firm!) wheels from King Motor RC

- Thrust bearings from VXB for keeping the steering servos from snapping their output splines

- Shafts, collets, springs, pins, and screws (all stainless!) from McMaster-Carr

- About twenty pounds of aluminum from Alan Steel, lovingly milled to shape on a Tormach CNC at the local TechShop workshop

- Some 3D printed plastic bits and bobs, as well as some laser-cut plywood, to interface and insulate various parts

Now, if I had to ask for something, I’d love to have motors one size stronger than the current 37D, still with gear boxes and encoders. I’m currently speed limited by the power of the motors; I tried 35:1 gearing and ended up burning out those motors, so 50:1 is the lowest gearing I can go, which with 7" wheels ends up with about 1.5 meters per second top speed.

And if I could ask for something else as well, I’d like a better fastening mechanism than D shafts, because there is a bit of a “wheels coming off” problem. I use 6mm reamed 24mm hexes to adapt to the wheels, and two 3mm set screws, but there’s still a sideways holding force problem:

Maybe I’ll put a 3mm hole in the shaft itself for the set screws to dig into, or maybe even just use a regular M3 screw at that point?