Hi!

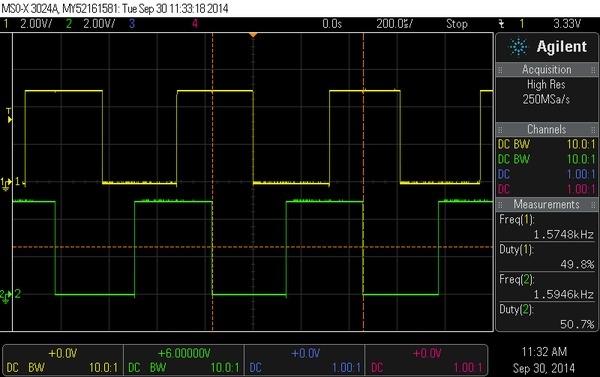

So I have a scope capture (crudely taken with a photo of the DSO scope…just got the scope recently and haven’t a way to install the software yet [no cd-rom drive].)

The capture is of the waveform of the two channels of a 3-star (there are 3 and 5 stars in the kit) equipped pololu micromotor encoder. Both channels are scaled to 500mV/block

So there are a couple things that I can figure out from the scope. (1), is that it seems one of the 3 fins are slightly farther away from the sensors than the other 2. I say this because the peak on both signals is slightly lower for one of the 3 peaks, and I interpret this to mean the reflectance of the IR led is less, so either the fin has less reflectance because the surface is marred physically, or it’s bent slightly backward. I hope this is a proper reasoning [not just me not knowing how things work.]

I also believe that my signals vary from the example pololu encoder signals insofar as they have a longer dead period, because the examples are all of the 5-star encoder wheel, not the 3-star encoder wheel. I hope my 3-star vs 5-star naming scheme has been clear (5-star meaning five-point star.)

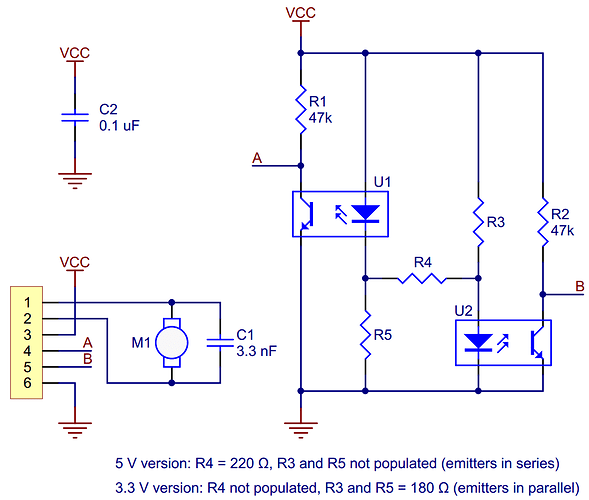

Anyway, what I’m still trying to work out is why one of my signals is much weaker than the other. One signal seems to be about 0.8V, and the other signal looks to be a much heartier 1.8 ish Volts. 1.8V is clearly in the territory of a HIGH on my 3.3v teensy 3.1 MCU, but 0.8V is slightly sketchier. But why would one sensor read such a lower value than the other? Could it be a smudge on the sensor or something? It is normal intrinsically to the sensor?

To be honest, I don’t know exactly what will trigger an interrupt on the teensy. Following the datasheet, a “HIGH” is 0.7Vdd, so 2.31V. That said I think that’s the HIGH that is produced by the MCU, not what triggers an interrupt using the quadrature encoder library. In fact, it seems to be working O-K, to be honest. So I imagine a HIGH can be triggered in the 0.6-0.8V range, OR, I’m running the encoder with only one output unbeknownst to me. Because the gearing of my system is a little unknown (random parts), I can’t easily figure out if the second output is working.

Eventually I plan on adding a comparator. It seems to me the examples say to calibrate to 50% duty on the signal, but that i could get away without doing that, so long as my interrupts can be handled fast enough even if the signal is 25%/75% (i.e, that the reason for calibrating to 50% is just so that you are HIGH as much as you are LOW, but I don’t know why else the comparator is used in that fashion.)

Thanks for any help. I appreciate learning more about this stuff, but I’m still ME and just learning.