Hello,

I am a Mechanical Engineering Student writing Thesis on Vibration Analysis of a Robot in a company.

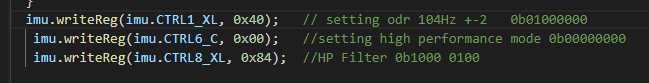

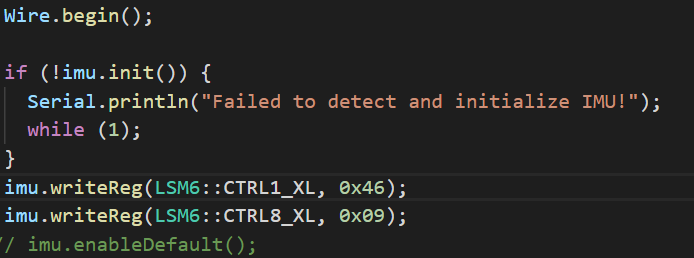

I ordered 3 LSM6DSO to measure the vibration of an Cartesian Robot. The sensor is read by the ESP32 and send it on my computer through Wifi. I first tried with I2C communication with the Code below:

#include <Wire.h>

#include <LSM6.h>

#include <WiFi.h>

const char* ssid = " ";

const char* password = "";

WiFiServer server(8686);

IPAddress local_IP(10, 45, 10, 4);

IPAddress gateway(0, 0, 0, 0);

IPAddress subnet(255, 255, 255, 0);

IPAddress primaryDNS(8, 8, 8, 8);

IPAddress secondaryDNS(8, 8, 4, 4);

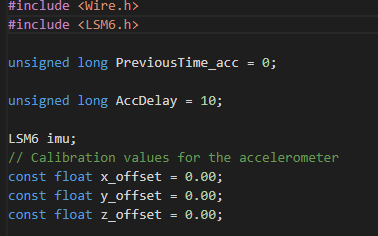

unsigned long PreviousTime_acc = 0;

unsigned long AccDelay = 30;

LSM6 imu;

// Calibration values for the accelerometer

const float x_offset = 0.00;

const float y_offset = 0.00;

const float z_offset = 0.00;

// Conversion factor from raw sensor values to g units

const float conversion_factor = 0.061 / 1000.0; //For +-2G

//const float conversion_factor = 0.122 / 1000.0; //For +- 4G : Roboter_acc = 2 m/s/s i.e großer als 2g so 4G ist besser

// const float conversion_factor = 0.488 / 1000.0; // For +-6G

void setup() {

Serial.begin(9600);

if (!WiFi.config(local_IP, gateway, subnet, primaryDNS, secondaryDNS)) {

Serial.println("STA Failed to configure");

}

Serial.print("Connecting to ");

Serial.println(ssid);

WiFi.begin(ssid, password);

while (WiFi.status() != WL_CONNECTED) {

delay(500);

Serial.print(".");

}

Serial.println("");

Serial.println("WiFi connected.");

Serial.print("IP address: ");

Serial.println(WiFi.localIP());

server.begin();

Wire.begin();

if (!imu.init()) {

Serial.println("Failed to detect and initialize IMU!");

while (1)

;

}

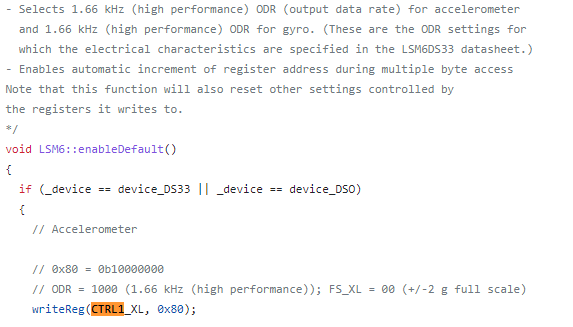

imu.enableDefault();

}

void loop() {

WiFiClient client = server.available();

if (client) {

Serial.println("New client connected!");

while (client.connected()) {

imu.read();

if ((millis() - PreviousTime_acc) >= AccDelay) {

float x = (imu.a.x * conversion_factor) - x_offset;

float y = (imu.a.y * conversion_factor) - y_offset;

float z = (imu.a.z * conversion_factor) - z_offset;

String report = String(millis()) + "," + String(x, 2) + "," + String(y, 2) + "," + String(z, 2) + ";\n";

PreviousTime_acc = millis();

Serial.print(report);

client.print(report);

}

}

Serial.println("Client disconnected!");

client.stop();

}

}

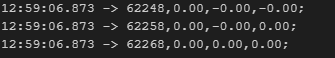

The Problem with I2C communication i am facing is that the data i m getting is not in every 30ms rather in 31ms sometimes. The data as Example looks like this: (millis(Timestamp), x,z, y)

8439 -0.00,-2.00,-0.02;

8469 -0.00,-1.98,-0.00; dt: 30 ms

8500 -0.00,-1.99,-0.01; dt: 31 ms

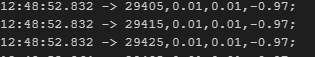

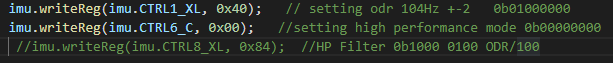

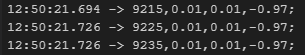

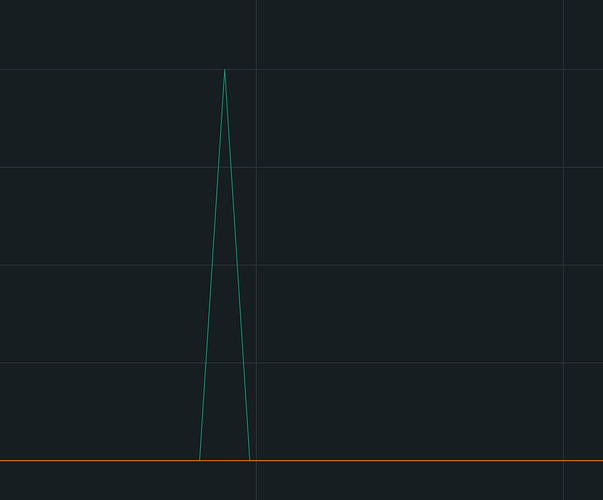

Similarly using SPI, it has better results but when i try to use in 100 hz or to say trigger read data in less than 30 ms, the data is lost in between. (Reading in 10ms)

232851 0.01,0.02,-0.98;

232861 0.01,0.02,-0.98; dt= 10ms

232985 0.03,0.02,-0.98; dt= 125ms

232995 0.03,0.02,-0.98; st = 10 ms

I dont know if the problem is with the type of communication i am using or i should consider other thing. The Datasheet says that it can read upto 6666hz. Thank you.

.

.