Hi…

I am trying to make a linefollowing robot and I am using the Pololu QTR-8Rc.

The materials I use:

- QTR 8 RC (6 sensors used)

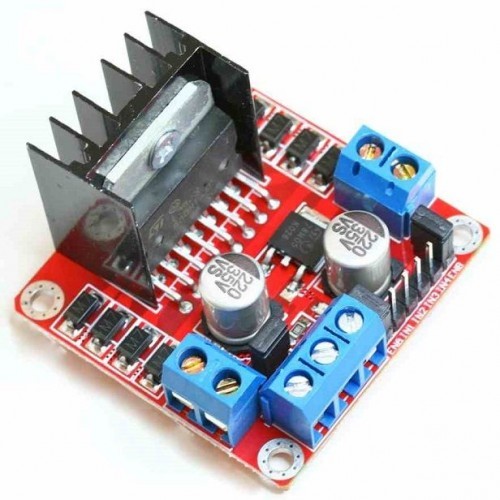

- Pololu L298N Motor Control

- 2 robotus profast 12v 3000 rpm Motors

Screen Preview attached… Does not follow the line Please Help ![]()

My Code :

#include <QTRSensors.h>

#define Kp .2

#define Kd 6.1

#define Ki 0.0015

#define maxRightSpeed 100

#define maxLeftSpeed 100

#define defaultRightSpeed 50

#define defaultLeftSpeed 50

#define numberOfSensors 6

#define TIMEOUT 2500

#define EMITTER_PIN 2

#define rightMotorForward 8

#define rightMotorBack 9

#define PWM_RIGHT 3

#define leftMotorForward 4

#define leftMotorBack 5

#define PWM_LEFT 6

#define STBY 13

QTRSensorsRC qtrrc((unsigned char[]) { 19,18,17,16,15,14} ,numberOfSensors, TIMEOUT, EMITTER_PIN);

unsigned int sensorValues[numberOfSensors];

/* ...... S E T U P ...... */

void setup()

{

/* OUTPORT PORT DEFINE. */

pinMode(rightMotorForward, OUTPUT);

pinMode(rightMotorBack, OUTPUT);

pinMode(PWM_RIGHT, OUTPUT);

pinMode(leftMotorForward, OUTPUT);

pinMode(leftMotorBack, OUTPUT);

pinMode(PWM_LEFT, OUTPUT);

pinMode(STBY, OUTPUT);

/* CALIBRATE START. */

delay(500);

pinMode(13, OUTPUT);

digitalWrite(13, HIGH);

for (int i = 0; i < 100; i++)

{

qtrrc.calibrate();

}

digitalWrite(13, LOW);

Serial.begin(9600);

}

/* ...... S E T U P END...... */

int previousError = 0;

int previousIntegral = 0;

/* WHITE/BLACK DEFINE.. */

bool isWhite=0;

bool isBlack=1;

/* ...... L O O P CODE START ...... */

void loop()

{

/* PRINT SENSOR VALUES... */

unsigned int position1 = qtrrc.readLine(sensorValues);

for (unsigned char sayac = 0; sayac < numberOfSensors; sayac++)

{

Serial.print(sensorValues[sayac]);

Serial.print('\t');

}

Serial.print(position1); //

Serial.print('\t');

/* END PRINT. */

/* PID... */

unsigned int sensors[6];

int position =qtrrc.readLine(sensors,QTR_EMITTERS_ON,isWhite); /* <<<<<<< WHITE ROAD BLACK LINE */

int error = 2500- position;

int Integral = error+previousIntegral;

int speedOfMotor = (Kp * error)/100 + (Kd * (error - previousError))/100 + Ki * Integral;

previousError = error;

previousIntegral=Integral;

/* PID END... */

/* NEW MOTOR SPEED... */

int speedOfRight = defaultRightSpeed + speedOfMotor;

int speedOfLeft = defaultLeftSpeed - speedOfMotor;

/*OPTIMIZED MOTOR SPEED... */

if (speedOfRight > maxRightSpeed ) speedOfRight = maxRightSpeed;

if (speedOfLeft > maxLeftSpeed ) speedOfLeft = maxLeftSpeed;

if (speedOfRight < 0) speedOfRight = 0;

if (speedOfLeft < 0) speedOfLeft = 0;

/* PRINT NEW VALUES... */

Serial.print("pid Motor Speed: ");

Serial.print(speedOfMotor);

Serial.print('\t');

Serial.print("Position: ");

Serial.print(position);

Serial.print('\t');

Serial.print("Error: ");

Serial.print(error);

Serial.print('\t');

Serial.print("Right New Speed: ");

Serial.print(speedOfRight);

Serial.print('\t');

Serial.print("Left New Speed: ");

Serial.println(speedOfLeft);

delay(500);

/* NEW SPEED WRITE... */

digitalWrite(rightMotorForward, HIGH);

digitalWrite(rightMotorBack, LOW);

analogWrite(PWM_RIGHT, speedOfRight);

digitalWrite(leftMotorForward, HIGH);

digitalWrite(leftMotorBack, LOW);

analogWrite(PWM_LEFT, speedOfLeft);

}

/* ...... L O O P E N D ...... */