Hello,

I am using the Jrk21v3 to drive a linear actuator, sending commands via serial input form a VBA-Programm, while using a power supply unit @~21V.

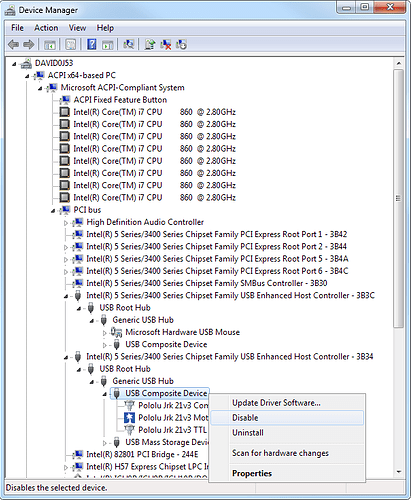

It occurs from time to time that the controller/motor wont react anymore and the green USB-LED turns off, the Plot window freezes and the Utility displays an error (see the end of this post).

The problem was reproducible with the VBA code and the Pololu Jrk Configuration Utility at various settings (USB Dual Port/Chained, Never Sleep on/off, PWM-freq 20/5kHz, different limits).

Sadly I could not figure out the cause of the error.

Can anyone help me out?

I hope I could provide enough information, let me know if not.

Thanks

See the end of this message for details on invoking

just-in-time (JIT) debugging instead of this dialog box.

************** Exception Text **************

System.Exception: There was an error turning off the motor. ---> System.ComponentModel.Win32Exception: Control transfer failed.

at Pololu.WinusbHelper.WinUsbDevice.controlTransfer(WINUSB_SETUP_PACKET setupPacket, Byte* buffer)

at Pololu.WinusbHelper.WinUsbDevice.controlTransfer(WINUSB_SETUP_PACKET setupPacket)

at Pololu.UsbWrapper.UsbDevice.MyWinUsbDevice.controlTransfer(Byte RequestType, Byte Request, UInt16 Value, UInt16 Index)

at Pololu.UsbWrapper.UsbDevice.controlTransfer(Byte RequestType, Byte Request, UInt16 Value, UInt16 Index)

at Pololu.Jrk.Jrk.motorOff()

--- End of inner exception stack trace ---

at Pololu.Jrk.Jrk.motorOff()

at Pololu.Jrk.MainWindow.setMotorState(Boolean motorOn)

at Pololu.Jrk.MainWindow.motorOffButton_Click(Object sender, EventArgs e)

at System.Windows.Forms.Control.OnClick(EventArgs e)

at System.Windows.Forms.Button.OnClick(EventArgs e)

at System.Windows.Forms.Button.OnMouseUp(MouseEventArgs mevent)

at System.Windows.Forms.Control.WmMouseUp(Message& m, MouseButtons button, Int32 clicks)

at System.Windows.Forms.Control.WndProc(Message& m)

at System.Windows.Forms.ButtonBase.WndProc(Message& m)

at System.Windows.Forms.Button.WndProc(Message& m)

at System.Windows.Forms.Control.ControlNativeWindow.OnMessage(Message& m)

at System.Windows.Forms.Control.ControlNativeWindow.WndProc(Message& m)

at System.Windows.Forms.NativeWindow.Callback(IntPtr hWnd, Int32 msg, IntPtr wparam, IntPtr lparam)

************** Loaded Assemblies **************

mscorlib

Assembly Version: 2.0.0.0

Win32 Version: 2.0.50727.3625 (GDR.050727-3600)

CodeBase: file:///c:/WINDOWS/Microsoft.NET/Framework/v2.0.50727/mscorlib.dll

----------------------------------------

JrkConfigurationUtility

Assembly Version: 1.2.1.0

Win32 Version: 1.2.1.0

CodeBase: file:///C:/Programme/Pololu/Jrk/bin/JrkConfigurationUtility.exe

----------------------------------------

System.Windows.Forms

Assembly Version: 2.0.0.0

Win32 Version: 2.0.50727.3623 (GDR.050727-3600)

CodeBase: file:///C:/WINDOWS/assembly/GAC_MSIL/System.Windows.Forms/2.0.0.0__b77a5c561934e089/System.Windows.Forms.dll

----------------------------------------

System

Assembly Version: 2.0.0.0

Win32 Version: 2.0.50727.3624 (GDR.050727-3600)

CodeBase: file:///C:/WINDOWS/assembly/GAC_MSIL/System/2.0.0.0__b77a5c561934e089/System.dll

----------------------------------------

System.Drawing

Assembly Version: 2.0.0.0

Win32 Version: 2.0.50727.3053 (netfxsp.050727-3000)

CodeBase: file:///C:/WINDOWS/assembly/GAC_MSIL/System.Drawing/2.0.0.0__b03f5f7f11d50a3a/System.Drawing.dll

----------------------------------------

Jrk

Assembly Version: 1.1.0.0

Win32 Version: 1.1.0.0

CodeBase: file:///C:/Programme/Pololu/Jrk/bin/Jrk.DLL

----------------------------------------

UsbWrapper

Assembly Version: 1.1.0.0

Win32 Version: 1.1.0.0

CodeBase: file:///C:/Programme/Pololu/Jrk/bin/UsbWrapper.DLL

----------------------------------------

Accessibility

Assembly Version: 2.0.0.0

Win32 Version: 2.0.50727.3053 (netfxsp.050727-3000)

CodeBase: file:///C:/WINDOWS/assembly/GAC_MSIL/Accessibility/2.0.0.0__b03f5f7f11d50a3a/Accessibility.dll

----------------------------------------

************** JIT Debugging **************

To enable just-in-time (JIT) debugging, the .config file for this

application or computer (machine.config) must have the

jitDebugging value set in the system.windows.forms section.

The application must also be compiled with debugging

enabled.

For example:

<configuration>

<system.windows.forms jitDebugging="true" />

</configuration>

When JIT debugging is enabled, any unhandled exception

will be sent to the JIT debugger registered on the computer

rather than be handled by this dialog box.