Some background:

I have a robot that runs on 16V (4S LiPo.) As a back-up, I also need to run the robot on 3S (12V.)

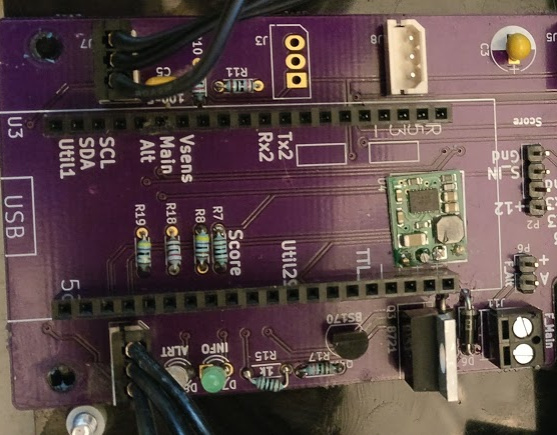

The controller for ther robot is an openCM 9.04 board.

This board has an input 5V regulator rated for 20V input, and a rated drop-out of 0.8 - 1.0V.

The board also has a large-ish input electrolytic capacitor (I think 100 uF?)

The board power draw is from a dozen to 50 mA. (Its main power sink is a STM32 ARM MCU and a 74125 style TTL bus driver.)

However, when I feed 16V straight into the board, the regulator gets hotter than I like, Dropping 50 mA from 16V to 5V is about 0.6W, so I can see why!

The board is rated 5V to 16V, but as I said, the input regulator is 0.8V drop-out and up to 20V input.

Solution: Get a D24V5F6 to put between the 16V battery and the power input on the OpenCM.

Given that the drop-out is rated between 0.8V and 1.0V, this should work fine, and leave the regulator as cool as possible.

Unfortunately, when I start up (a MOSFET based power switch,) what happens is that the board power LED just glimmers weakly, and the board doesn’t get to the start-up code that blinks anoter LED. It seems to be in brown-out.

Measuring the output from the D24V5F6 at this point shows about 3V output! It never goes out of this mode.

When the OpenCM is not plugged in, the D24V5F6 starts up fine, and outputs 6.06V, which is perfect.

When the OpenCM is plugged in, and I don’t use the D24V5F6 , it runs fine. (But the linear regulator gets hot.)

Knowing how finicky switching controllers can be (they’re really just oscillators with a negative source impedance, and might easily go into all kinds of weird feedback loops,) I wonder if there’s something in this setup that causes the D24V5F6 to latch in “bad” mode on start-up. Something like over-current beacuse of inrush, or some unfortunate interaction with the particular rise time and power spike when the MCU first powers out of brown-out, perhaps?

Does this ring any kind of bell? Is there some kind of easy fix you know about?

I have other options, such as a 7.5V buck converter, or a linear regulator instead of the switcher. But the 6V looks so nice, and leaves everything so cool, in theory, so I’d love to get it to work!