Hi Brandon,

Thanks for the reply, it sound as it would be possible to use these kind of LED’s.

I think the APA102c will be the best choise, because the ‘bus’ is not the same in length between the LED’s and this will influence the timing of the signals.

A new question I do have

What will happen to the LED’s when they are wrong connected to VCC/GND/Di/Ci?

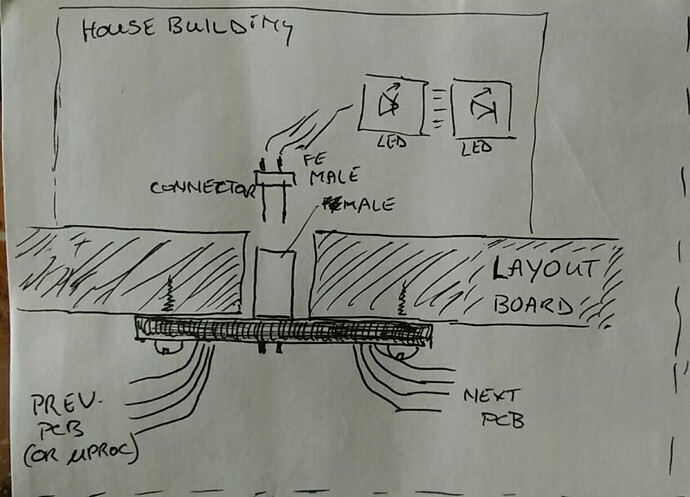

All the buildings will be removed/placed on the layout during years of construction. And when a part of the layout will be finished 1 or 2 building will be removed/replaced for maintenance. The LED’s will be positioned in the buildings (every building 1~8 LED’s) and connected by small connectors. The lights will be switched on/off according time of the day … livingroom, bedroom, etc.

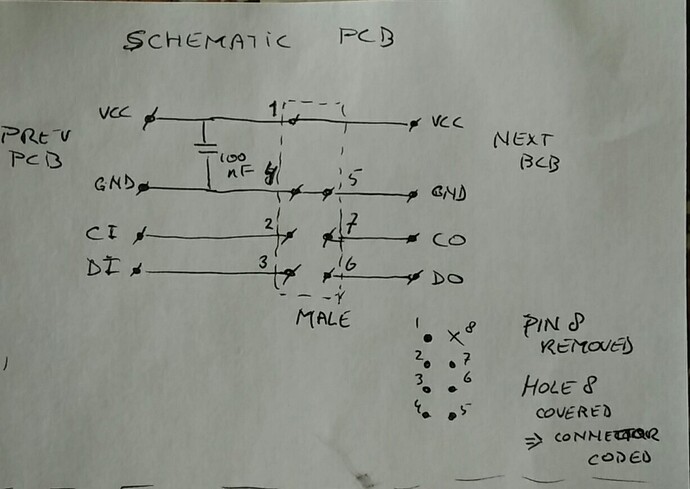

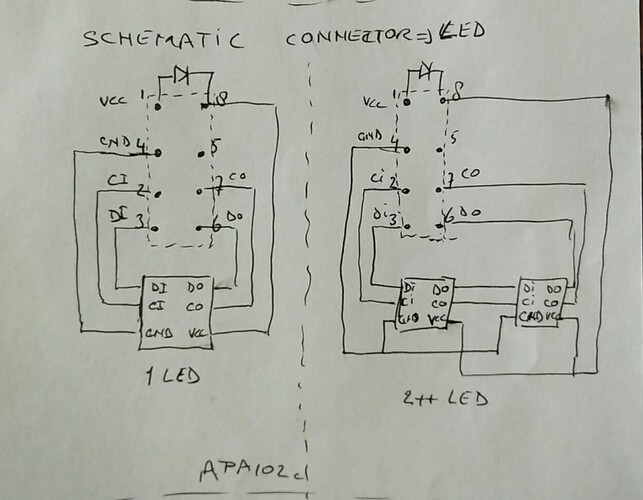

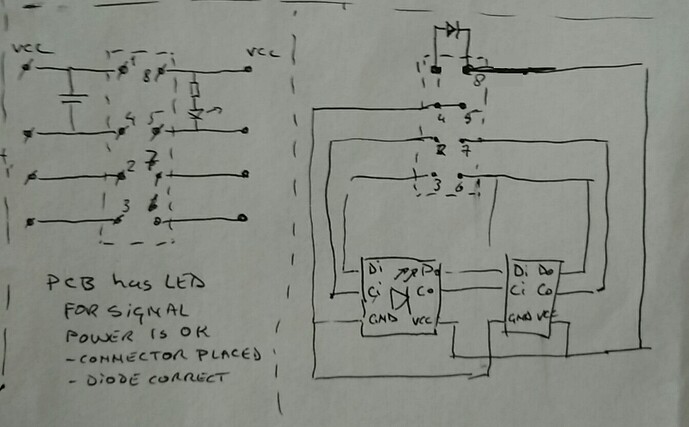

To make this possible, we want to make a small PCB - with a 2x4 connector - below the layout-board and wire the LED’s to the opposite-connector. The type will be like https://www.pololu.com/product/1024 and a part of https://www.pololu.com/product/966.

With these type of connectors it is (of course) possible to position them wrong to each other…

It is possible to shift the positions or rotate them over 180 degrees and shift them as well…

I can and will protect the VCC powersupply for the LED-string in every building with a diode.

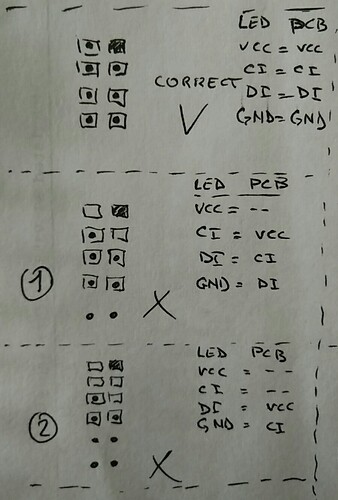

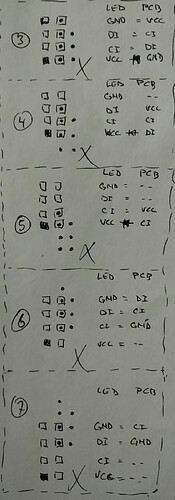

The first option I have is a ‘coded’ connector-set, 1 male-pin cut away and 1 female-hole blocked. But that will only be a part of the solution, shifting is still possible. And it is possible to connect VCC/GND to Di,Ci of the LED’s. See the attachments.

The second option is a PCB with a small LED to show the correct position of the connector, VCC and GND are correct connected by the male-header,

the LED is on (visual check) or opto-coupler will signal correct position to the controller (which will start the data).

So what is the risk for the LED’s when they are wrong connected?

What will happen?

For APA102c:

Case 1/2 - connector shifted ‘up’:

=> LED’s wire

- VCC = not connected

- Ci = connected to VCC

- Di = connected to Ci

- GND = connected to Di

.or.

- VCC = not connected

- Ci = not connected

- Di = connected to VCC

- GND = connected to Ci

Case 3 - connector rotated 180 degr.:

=> LED’s wire

- VCC = connected to GND (protected by diode, so safe)

- Ci = connected to Di

- Di = connected to Ci

- GND = connected to VCC

Case 4/5 - connector rotated 180 degr. and shifted ‘up’:

=> LED’s wire

- VCC = connected to Di (with diode but powered when data is active)

- Ci = connected to Ci

- Di = connected to VCC

- GND = not connected

.or.

- VCC = connected to Ci (with diode but powered when data is active)

- Ci = not connected VCC

- Di = not connected

- GND = not connected

Case 6/7 - connector rotated 180 degr. and shifted ‘down’:

=> LED’s wire

- VCC = not connected

- Ci = connected to GND

- Di = connected to Ci

- GND = connected to Di

.or.

- VCC = not connected

- Ci = not connected

- Di = connected to GND

- GND = connected to Ci

Case PCB with opto-coupler:

- Connection for VCC and GND are checked before data will be started.

- Of course this so;ution can be made more sophisticated

with regards,

Willie