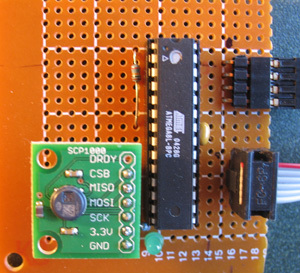

…and it’s totally awesome! Actually, it worked last night, but I didn’t get around to posting it. I struggled for a few hours before realizing that I had neglected a pull-down resistor for the MISO line, which I put a protection diode on for when the LCD was running. I even missed it looking with an osciliscope, since I connected it to the anode side of the diode. Anyway, here’s the overly long single file code:

/*SCP1000 Pressure Sensor SPI Test for Atmega8 Orangutan

Adam Borrell

Mobile Robotics Lab

University of Michigan

6/30/07*/

#define LCD_Clear 0x01

#define LCD_Line1 0x80

#define LCD_Line2 0xC0

#define F_CPU 8000000UL

#include <avr/io.h>

#include <util/delay.h>

void SPI_MasterPreInit();

void pressureInit();

void pressureWrite(unsigned char addr, unsigned char data);

int pressureRead16(unsigned char addr);

void LCDInit(void);

void LCDSendData(unsigned char data);

void LCDSendCommand(unsigned char command);

void LCDPrintString(const unsigned char *string);

void LCDGotoXY(unsigned char x,unsigned char y);

int main(){

unsigned char buf[8];

int i,j=0;

DDRD|=(1<<PD1);//set LED pin to output

PORTD|=(1<<PD1);//turn on LED

SPI_MasterPreInit();

pressureInit();

LCDInit();

while(1){

if(PINC&(1<<PC4)){//new data ready

PORTD^=(1<<PD1);//toggle LED

SPCR=(1<<SPE)|(1<<MSTR)|(1<<CPHA)|(1<<CPOL)|(1<<SPR0);//Enable SPI (takes over MISO function), Master, set clock rate fck/16 (500KHz)

itoa(pressureRead16(0x20),buf,10);

SPCR&=!(1<<SPE);//Disable SPI (releases MISO function)

LCDSendCommand(LCD_Clear);

LCDSendCommand(LCD_Line1);

LCDPrintString(buf);

itoa(++j,buf,10);

LCDSendCommand(LCD_Line2);

LCDPrintString(buf);

}

}

return 0;

}

void SPI_MasterPreInit(){//initialize SPI without enabling/compromising LCD pins

PORTC|=(1<<PC5);//bring PC5 high first

DDRC|=(1<<PC5);//Set PC5 (my chosen SS) to output

DDRC&=~(1<<PC4);//Set PC4 (Data Ready Interrupt) to input

DDRB|=(1<<PB2)|(1<<PB3)|(1<<PB5);//Set SS (must be output or externally brought high), MOSI and SCK output, all others user defined

}

void pressureInit(){

int i;

for(i=0;i<5;i++){

_delay_ms(20);//startup delay

}

SPCR=(1<<SPE)|(1<<MSTR)|(1<<CPHA)|(1<<CPOL)|(1<<SPR0);//Enable SPI (takes over MISO function), Master, set clock rate fck/16 (500KHz)

pressureWrite(0x02,0x2D);//Configure SCP1000 with low noise configuration

pressureWrite(0x01,0x03);

pressureWrite(0x03,0x02);

for(i=0;i<5;i++){

_delay_ms(20);

}

pressureWrite(0x03,0x0A);//Select High Resolution Mode

SPCR&=!(1<<SPE);//Disable SPI (releases MISO function)

}

void pressureWrite(unsigned char addr, unsigned char data){

PORTC&=!(1<<PC5);//bring SS Low

SPDR=((addr<<2)|(1<<1));//Transmit shifted address with write bit

while(!(SPSR&(1<<SPIF)));//Wait for transmission complete

SPDR=data;//transmit data

while(!(SPSR&(1<<SPIF)));//Wait for transmission complete

PORTC|=(1<<PC5);//bring SS high

}

int pressureRead16(unsigned char addr){

int data=0;

PORTC&=!(1<<PC5);//bring SS Low

SPDR=(addr<<2);//Transmit shifted address with read bit

while(!(SPSR&(1<<SPIF)));//Wait for transmission complete

SPDR=0x00;//transmit blank data to generate clock ticks

while(!(SPSR&(1<<SPIF)));//Wait for transmission complete

data=(SPDR<<8);//grab bits

SPDR=0x00;//transmit blank data to generate clock ticks

while(!(SPSR&(1<<SPIF)));//Wait for transmission complete

data|=SPDR;//grab bits

PORTC|=(1<<PC5);//bring SS high

return data;

}

/*

Send lower 4 bits of data byte to display

*/

void LCDSendNibble(unsigned char data){

data&=0x0F; //lower 4 bits of data

data<<=3;

PORTB&=~0x38; //clear LCD bus bits 456

PORTB|=(data & 0x38); //or in data

data<<=1;

PORTD&=~0x80; //same for top bit on PORTD.7

PORTD|=(data & 0x80);

_delay_us(1);

PORTD|=(1<<4); //E = 1

_delay_us(2); //required minimum 1 us delay

PORTD &= ~(1<<4); //E = 0

_delay_us(1);

}

/*

Send a character to the LCD display

*/

void LCDSendData(unsigned char data){

PORTD&=~(1<<3); //R/W =0

PORTD|=(1<<2); //RS = 1;

LCDSendNibble(data>>4);

LCDSendNibble(data);

_delay_us(100); //38 us typically needed to complete this action

}

/*

Send a command to display. Required delay time depends on the command and the

LCD controller clock frequency -- here assumed to be the minimum 190 kHz

*/

void LCDSendCommand(unsigned char command){

PORTD&=~(3<<2); // R/W=0, RS = 0;

LCDSendNibble(command>>4);

LCDSendNibble(command);

_delay_ms(3); //maximum required is 2.1 ms for "clear display"

}

// print a string constant

void LCDPrintString(const unsigned char *str){

while(*str!=0)LCDSendData(*str++);

}

// set print position to (x,y) where y=line number (0 or 1), x = character position 0, 1, etc.

void LCDGotoXY(unsigned char x, unsigned char y){

volatile unsigned char ddram_addr;

ddram_addr=0x80; //initialize data ram address to 0 (default)

if(y==1)ddram_addr=0xC0; //start print at line 2, DDRAM address 0x40

LCDSendCommand(ddram_addr+(x&0x7F));

}

/*

Initialize the LCD Display, timing requirements taken from datasheet

Set PORTB.3,4,5 to DB 4,5,6

Set PORTD.2,3,4,7 to RS, R/W, E and DB7

Send required start-up sequence to set 4 bit interface, 2 lines, 5x8 characters and clear display

*/

void LCDInit(void){

DDRB|=(7<<3);

DDRD|=(1<<7)|(7<<2);

PORTD&=~(7<<2); // E=0,R/W=0, RS = 0;

_delay_ms(20); //required startup sequence from power-on (see datasheet)

LCDSendNibble(0x03); //set interface=8 bits

_delay_ms(10); //wait at least 5 ms

LCDSendNibble(0x03); //set interface=8 bits

_delay_ms(1); //wait at least 100 us

LCDSendNibble(0x03); //set interface=8 bits

_delay_ms(1); //wait at least 100 us

LCDSendNibble(0x02); //set interface=4 bits

_delay_ms(1); //delays after this are built into SendCommand

LCDSendCommand(0x28); //set interface=4 bits, 2 lines, 5x8 characters

LCDSendCommand(0x08); //display off, cursor off, blink off

LCDSendCommand(0x01); //clear display

LCDSendCommand(0x06); //entry mode set, cursor shifts right after character rcvd.

LCDSendCommand(0x0D); //0b01DCB D=1:Display on, C=1:cursor on, B=1:Blink on

}

-Adam