Hi again david!

So today I made a lot of tests and I have other informations about the problem of the jrk lost connection.

Here the vids of what my platform do and what ask to the jrk12v12 :

You can see that sure I am asking much to my little jrk but they works really good!!

I tried many settings about PID, duty cycle, accelleration, pid period and integral limit too and I find a better and more precise behaviour of my motion system but unfortunately the “lost connection” error back today and many times.

From what I understand (and I am 80% sure about) more the motor get effort more the percentage of possible error grows.

I lowered the duty cycle and accelleration and I get less errors.

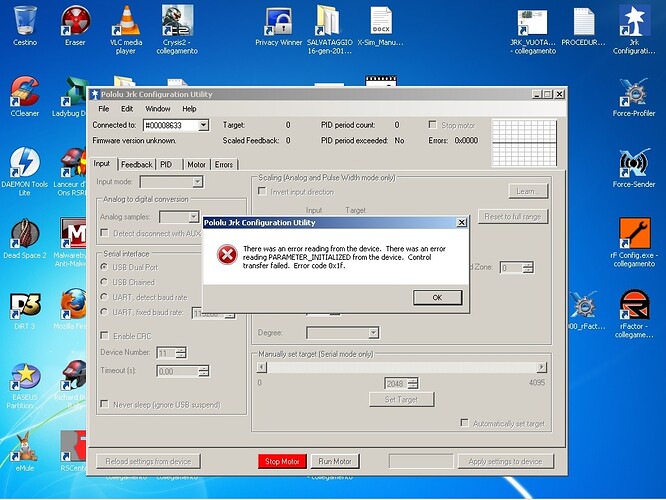

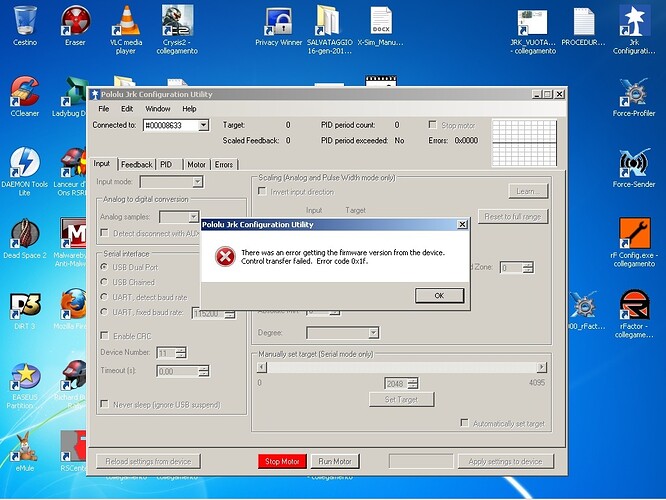

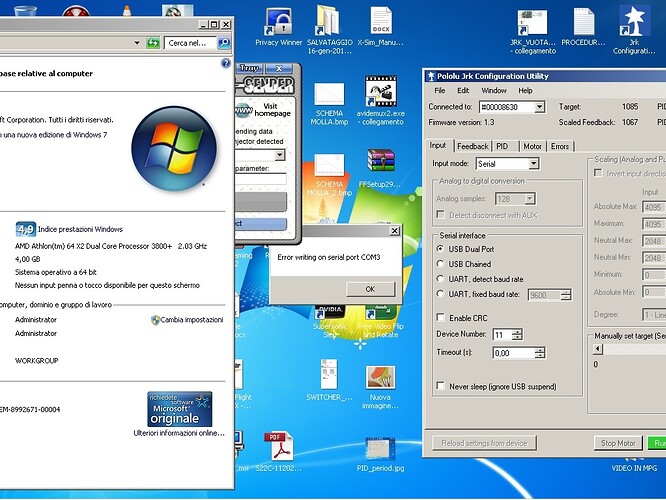

Here the errors:

And now the news! When I get the error (or the first pic error or the second too) I watched the device manager and I see that the situation here is the same of when all the 3 jrk are working without problems.

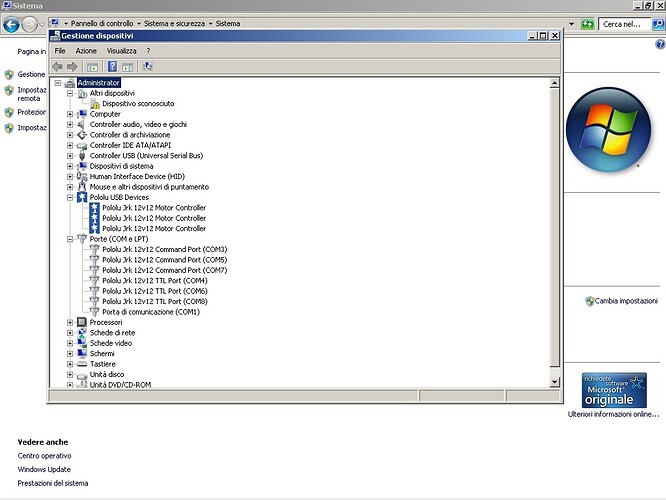

here the pic, I have this exact situation when my 3 jrk are working good and when one or more jrk stop to working after a connection lost:

See the next REPLY of this thread to see the device manager pic! I can’t attach more of 3 pics!

Do you think you can handle the problem with the reset method which you were talking to me? or making a new firmware making in automatic this reset?

And I notice too that the jrk had the green and yellow flashing lights exactly like when they are working correctly and powered (other day I told you that there was just the yellow light but I think I was mistaken).

So when I get this error I can’t to move the motor from jrk config utility, I can’t move the motor from x-simulator (the software I am using for my motion system) and I must to unplug and replug the jrk to back to have control of it.

When I replug the jrk then I can move again the motor from the jrk config utility and from x-sim too.

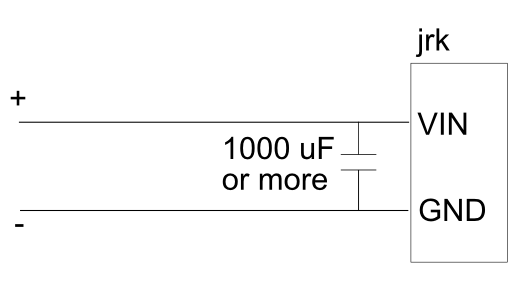

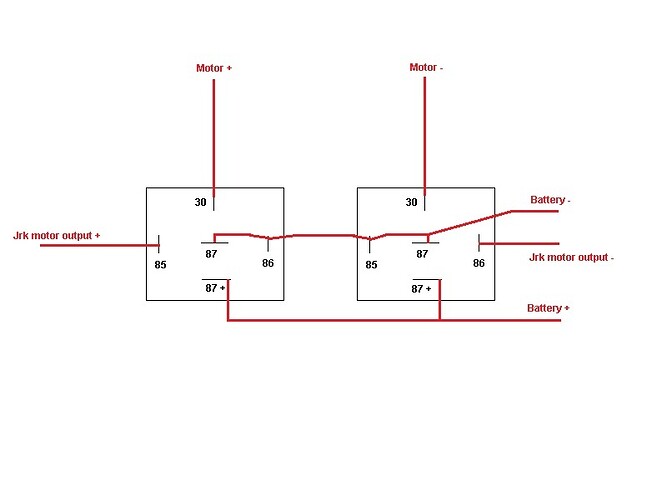

Thank you for the scheme, I speak about that to my electrician team mate! I MUST to solve this problem and all the theoretical solutions are loved here!!!

and remaining in the “external components” matter to solve this bad problem, please, take a look to next reply of this thread to see the pic of the schema about 6 relays that should solve finally this bad connection lost error.

I already test this method time ago and WORKS!! No more the jrk providing the current from batteries to the motor!

The relays will think about the motor power alimentation and with this method I can get ALL the truly motor power with really less suffering for the little jrk!.

In fact the jrk will handle just the order to positions and feedback so I am pretty sure (I hope!!!) that no more problem related to too many amps request from motors or bad and very big amps peaks!.

Please tell me what you think about!.

I stop to use this method just cause I was pretty sure I could use directly the jrk to handle without problems my winches motors… but as you told, probably I am a bit over the jrk12v12 performances…

A last thing, why 2 same models car batteries in parallel is not a best choice?

For now again thank you a lot, your help it’s really precious mate and sorry for my bad english…

Already tested, from jrk config utility moving the motor (with a pot for feedback) on various positions, clockwise and anticlockwise, exactly as I am using my system without the relays)

Already tested, from jrk config utility moving the motor (with a pot for feedback) on various positions, clockwise and anticlockwise, exactly as I am using my system without the relays)