Hello,

#UPDATE: Read my replies to this thread. I think I have things working as hoped for.

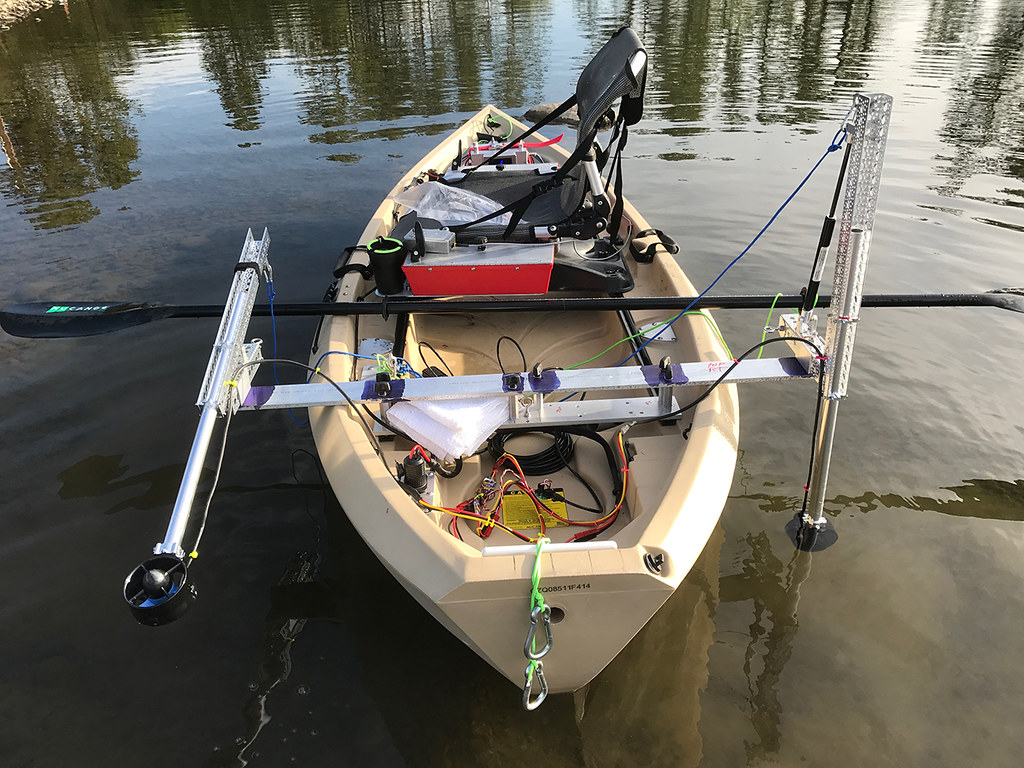

I need some help taking my fishing kayak propulsion project to the next level. I have been using Pololu controllers for several years now and have been extremely happy with the results.

My initial designs used off the shelf brushed motor trolling motors but I am now using BlueRobotics T200 thrusters. with their “Basic ESC”.

I have been using a Pololu Micro Maestro 6-channel to control the thrusters. I have the Micro Maestro configured with three inputs from 10k Ω potentiometers. Two of the pots control two thrusters and the third pots controls a servo for steering.

I have two setups for my propulsion systems.

One is transom mounted like a standard transom mounted trolling motor, where the thruster(s) are controlled by one or two channels from the Mini Maestro and steering, is accomplished via a servo connected to the thrusters via a shaft through the tiller. I call this active vectored steering.

The other is a “skid steer” setup where the thrusters are mounted “outrigger” style. The thrusters are fixed and steering is accomplished by varying the speed and direction of each thruster. I call this passive vectored steering.

Here is my current settings file:

Please note: I am now using a Pololu Mini Maestro 12-channel controller

I switched from the Micro to Mini because I thought I might need some of the additional scripting commands on the Mini.

maestro_settings 07222017 mini12 joystick001.txt (3.3 KB)

This current setup is very basic and works well.

I am now testing out using a joystick setup to do the same thing but there are some obvious differences between using individual pots and a joystick setup.

The joystick I am testing is more or less a standard configuration. It is a 4-function joystick I picked up from ServoCity.

It has an X, Y & Z axis. All axis are connected to 5k pots and are “return to center”.

There is also a N.O. push button switch on the top of the joystick lever.

This joystick setup works just like my individual potentiometers setup.

Here is what I am trying to accomplish.

I want to be able to set the speed and direction of my two thrusters with the joystick AND then have the have controller hold those values. My thinking was that the push button on the joystick could be used to tell the Mini Maestro to hold/release the values.

Real world description: I want to be able to set the direction and speed of my kayak with this controller via the joystick and then be able to take my hand off the joystick and have the speed and direction “hold” until I want to make changes.

I could use some help with the scripting. Hopefully someone has already done some like this.

I am also willing to “hire” someone to do this for me.

Thanks in advance for any help and/or advice.

Phil