This is probably not your big problem, but it is something that has come up before, and I was doing it wrong for a while myself.

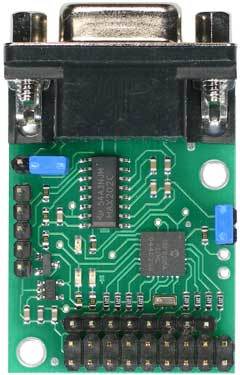

The servos are powered directly from the power source you connect to the servo power pins (you can see the big fat traces on the circuit board). The 4V-6V range is normal for hobby servo power. Meanwhile, the VIN pin powers the servo controller board’s microcontroller through a voltage regulator, so you can connect 5V-16V to it, and the regulator will drop that voltage down to the 5V that the microcontroller uses for normal operation.

The Vcc=Vs jumper connects the servo power line directly to the microcontroller, bypassing the regulator! so if you connect 6V to your servo power you’re actually connecting 6V to the microcontroller! Worse yet, if you use, say, a 5 cell NiMH battery pack, with a nominal 6V, you can actually see 7V with a fresh full charge! The microcontroller is designed for up to 5.5V, with an absolute maximum voltage of 6.5V, meaning that applying 6V to it won’t smoke it immediately, but don’t make a habit of it.

I find this graphic to be quite helpful, it’s based on the micro-serial servo controller, which is mostly the same board but without the 9-pin serial connector:

I like keeping the microcontroller safely behind the voltage regulator (protects from damage from voltage spikes, suppresses interference from motor noise), so I usually don’t use the Vcc=Vs jumper. If your power supply is between 5V and 6V there’s no reason you can’t wire it to both the servo power and VIN pins, just be sure to leave off the VCC=VS in that case!

ANYWAY, down to diagnosing your actual problem. With your servo controller disconnected from your computer, when you connect a power source (5V-16V) to the VIN and GND pins, you should see some LEDs turn on (either just the yellow one, or all three, depending on things I forget at the moment). If no LEDs come on at all when you do this something is very wrong. My first guess would be that power isn’t getting to the microcontroller.

You wouldn’t happen to have a multimeter with a continuity tester, would you? It makes it really easy to check your soldering connections.

-Adam