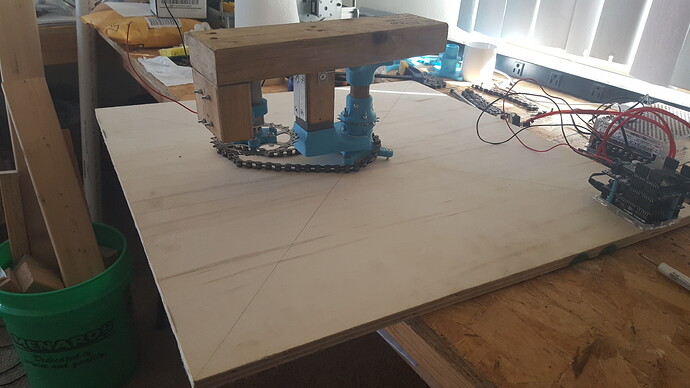

I’ve been working on a project for the past couple weeks to spin a painting (about 2x2’ of 1/2" plywood) using a DC motor (part number 3207) and a custom, 3D printed mechanical system.

Previously I did some calculations (Advice for right DC motor to spin a painting - #2 by grant) and found that it seemed like the motor would be more than powerful enough for this application, and things were looking good until a few moments ago.

However, I’m using bike chain and bike gears to spin my painting, and when I tried to install the chain manually by spinning the motor a few degrees, the gears inside the gearbox broke. Now when I apply power I get no movement, only sound.

The piece needs to be finished by Friday, so I’m trying to figure out whether I need to source a different motor, or if I should replace the one I originally got.

If I use the same motor, but never spin it manually, are the gears likely to just snap again? I’ve never used these motors, so I don’t know how strong their gears are, but if they are rated for 300oz-in, it seems reasonable that the gears would be able to handle that spec as well.

Video of broken movement: Broken gears Pololu motor - YouTube