Hi all, I have bought several pololu-micro metal gearmotors, and I’ve had problems with a robot built with 4 1:150 HP micro metal gearmotors pololu.com/product/997.

The page says that they can run in the range of 6-9 volts so I powered them with around 8,5-9 volts in order to get more performace.

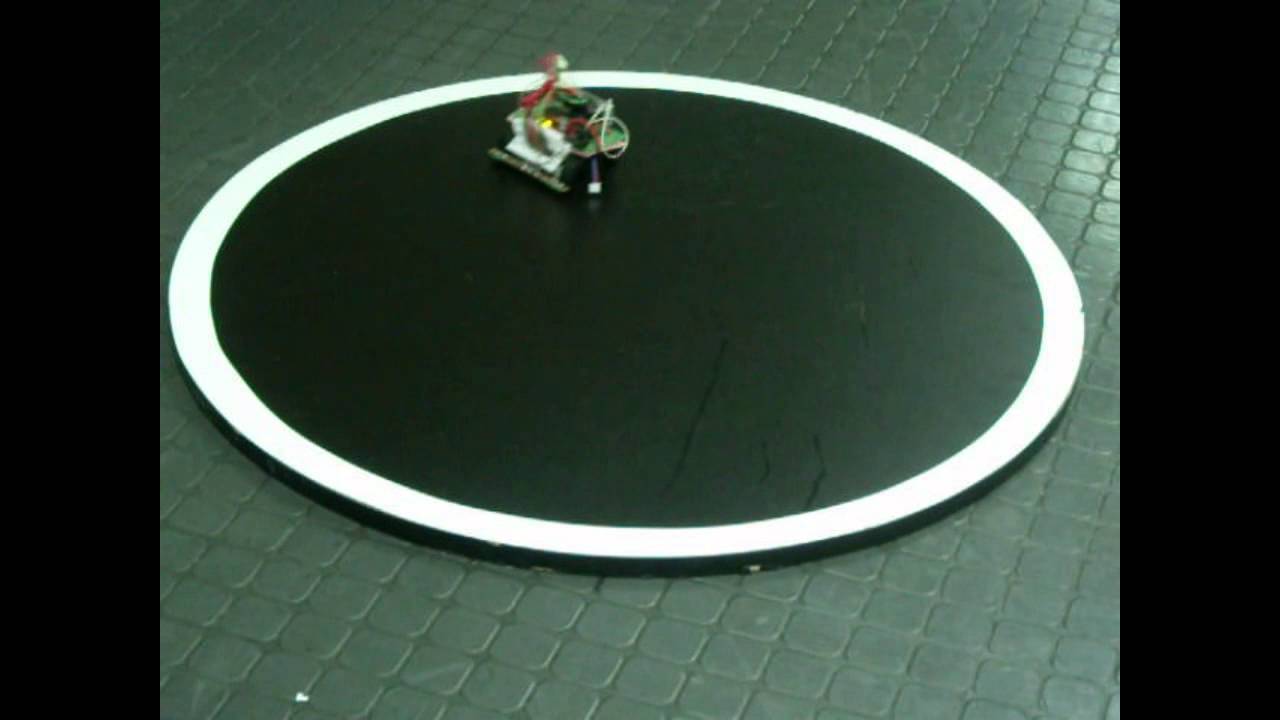

You can see a video comparison of 6 volts working and 8,5 volts working, both of them filmed before the problem

Some days after that (were I tested the robot at constant 8,5v) three out of the four motors stopped working during a testing. I noticed they had some heat touching them with my finger.

I concluded they were broken and checked what happened inside them:

A little packing ring was detached from the motor, I think maybe because of heat, the gearbox stage though, survived. I think that the heat was the problem and not the torque because of that (also the robot was not stalled when they stopped working)

The important detail here is the PWM I used, that was around 1khz, maybe less because it was made without pic18f4550 pwm (that was used for generating 38khz for the IR sensors), and in the normal program (a counter variable going from 0 to 10, and checking if the variable was lower than the speed to decide motor status), and also I was using two lipo 7,4v connected in series (getting a total of 14,8 volts, reduced by the l298 H-bridge to nominal value of 8,5, but with 1khz frequency, I’ve seen people in the internet using up to 20 khz motor freq).

Also that time I didn’t use l298n protecting diodes but yes a 104 ceramic capacitor around the motor poles.

Because of that currently my robot uses nominal voltage of 6v in that pwm that reduces from 7,4v to 6v (but as the l298n H-bridge has around 1v drop, my robot in 100% speed has no pwm at all (100% duty cycle equals to almost 6v motor power)

I have lot of questions, for example, if I use a higher frequency, that makes motor to handle better high voltage and extend motor lifetime?), Can I use 13,8volt of pwm peak voltage but nominal 6v, what damage the motor, the peak of 13.8v or the nominal? The frequency determines that?

If I use LiPo 11.1v (10v with l298n 1v drop) instead of two 7,4 volt, and reduce it with pwm to 6 volt (maybe only 7-8-9v for a second only) I extend motors life time?

Can I use low frequency (500-1000 hz), or in order to protect motors and assure they won’t break I must use higher frequencies?

If I use l298n protecting diodes circuit, 4tronix.co.uk/arduino/pictur … dge_02.jpg will I get improvements?

Also I have another question about robot traction. I am currently using four solarbotics high traction wheels pololu.com/product/642. I noticed they start to turn in the air if the push more than their maximum traction. In order to improve traction I clean them with alcohol from time to time. Is valid if I say that using that high torque motor has no sense because the wheels traction limitation? So It’s better to switch to lower gear ratios because the higher torque can not improve robot effective push? (so preferable more speed). I changed the robot to two 1:50 motors and four 1:30 motors separately and the result is the same, when pushing something too heavy the wheels turn in the air but I am not sure if there was a change in the robot maximum push, should it be a change?

Also last question, I am currently setting the pwm the L-298n bridge in the motors output directly

a) can I set it on the enable pins?

b) Is there some changes doing that?

st.com/web/en/resource/techn … 000240.pdf

![]()